The Wood Material Engineering Laboratory (WMEL) at Washington State University in Pullman developed the product with Madison, Wis.-based Strandex Corp. for the Office for Naval Research. “We developed UMM to replace components on docks and piers where owners prefer to avoid chemical treatments to resist decay,” said Michael Wolcott, a professor of civil engineering at WSU and the research director at WMEL.

It is made from a combination of finely ground sawdust, recycled plastic and special additives. Because it isn’t treated, the product is a desirable choice when planners want to avoid permitting delays. “When using UMM, builders and developers won’t have to go through a time-consuming environmental permitting process that comes into play when using treated lumber,” said Gary Maulin, sawn products manager of McFarland Cascade.

It is made from a combination of finely ground sawdust, recycled plastic and special additives. Because it isn’t treated, the product is a desirable choice when planners want to avoid permitting delays. “When using UMM, builders and developers won’t have to go through a time-consuming environmental permitting process that comes into play when using treated lumber,” said Gary Maulin, sawn products manager of McFarland Cascade.

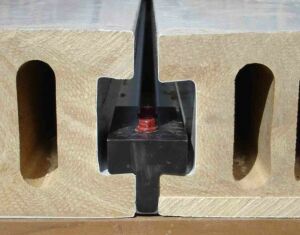

The grey weather-resistant PVC cap offers consistent appearance long after traditional wood decks crack, splinter and age. The patented clip installation system offers an alternative to screws or nails on the surface and reduces installation time and costs. It also allows for expansion and contraction of the decking.

The grey weather-resistant PVC cap offers consistent appearance long after traditional wood decks crack, splinter and age. The patented clip installation system offers an alternative to screws or nails on the surface and reduces installation time and costs. It also allows for expansion and contraction of the decking.

UMM was recently used for a footbridge spanning 90 feet at the Rattlesnake Wilderness and National Recreation Area in Missoula, Mont (pictured). It has also been used for various demonstration projects at the University of Pennsylvania and at WSU and will also be installed for a 300-foot wave screen sheltering a marina at the U.S. Naval Academy in Annapolis, Md.

(Cf. news of 2005-10-07 and 2004-05-28.)

Source

NetComposites, 2007-06-18.

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals