The current discussion on the prohibition of lightweight plastic bags has now reached the entire European Union. According to the EU Commission, 198 plastic bags on average were used for each citizen across the EU; in Germany the number was 71. Most of these are made of lightweight plastic and are therefore often used only once, compared to bags made of sturdier material. Even if their actual life cycle is relatively short, lightweight-plastic bags can remain intact for hundreds of years and can end up in the ocean as harmful microscopic particles, thereby causing lasting damage to plants and animals.

According to a press release dated 19 December 2013, the German Bundesrat considered the pressures on the sea due to plastic waste. This is viewed as a serious problem and they support the objective of the EU proposal to reduce consumption of these lightweight plastic bags in Europe. At the same time, it points out that further appropriate measures are essential in order to sustainably combat the accumulation of persistent plastic waste on land and sea. The Bundesrat therefore also supports efforts to reduce the inappropriate disposal of plastic waste.

It criticizes, however, the fact that the Commission proposal focuses solely on reducing consumption, without taking into account the extremely diverse situations in the member states. Germany, for instance, has an existing and credible collection and recycling infrastructure.

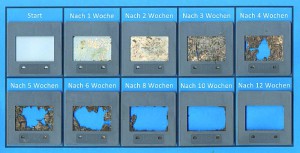

And today there are already environmentally friendly, marketable solutions involving biodegradable plastics. The bioplastics made by Metabolix Inc., mirel® and mvera®, biodegrade within a short period when in contact with the ground (compost) and water (river, ocean), as well as in biogas plants. A study published by the Organic Waste Systems Institute in Belgium shows that plastic bags made of mvera® with a wall thickness of 288 µm were completely decomposed by bacteria within 12 weeks.

Metabolix makes its bioplastics primarily from polyhydroxyalkanoate (PHA). PHA is obtained through microorganisms and sugar in a biological process. The bioplastics are made in a fermentation, extraction and compounding step. Thus several environmental objectives are achieved at once such as the substitution of crude-oil-based raw materials, meeting of climate protection objectives, reduction in the amount of waste, avoidance of pollution of natural environment and an ecological production process.

Metabolix makes its bioplastics primarily from polyhydroxyalkanoate (PHA). PHA is obtained through microorganisms and sugar in a biological process. The bioplastics are made in a fermentation, extraction and compounding step. Thus several environmental objectives are achieved at once such as the substitution of crude-oil-based raw materials, meeting of climate protection objectives, reduction in the amount of waste, avoidance of pollution of natural environment and an ecological production process.

The plastics distributor K.D. Feddersen GmbH & Co. KG markets the mirel® and mvera® products and provides consulting support for waste prevention. Applications realized to date in the area of agriculture are a source of ideas for further products made of bioplastics, beyond packaging materials.

Thus clips for grape vines and for growing vine vegetables are already being made from this sustainably produced material (see Fig. right). The natural degradation process does away with the need for the expensive collection and disposal of these plastic parts. Further raw material developments with functional surface treatment in the area of horticulture and long-fibre-reinforced plastics for injection-moulding will soon be available.

Your contact:

K.D. Feddersen GmbH & Co. KG

Marc Swatosch

Gotenstraße 11 A

20097 Hamburg

Germany

Tel.: +49 40 23507 01

Fax: +49 40 23507 250

marc.swatosch@kdfeddersen.com

Source

K.D. Feddersen GmbH & Co. KG, press release, 2014-02-06.

Supplier

Deutscher Bundesrat

European Commission

European Union

K.D. Feddersen GmbH & Co. KG

Metabolix

Organic Waste Systems (OWS)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals