RadiciGroup Performance Plastics’ contribution to the second edition of Performance Polyamides 2017 – taking place on 6 and 7 June 2017 in Cologne – is a presentation by Erico Spini, marketing manager Europe, and Nicolangelo Peduto, R&D director, in conjunction with an exhibition space dedicated to new products already available on the market. A must-attend event for all industry operators, the conference highlights the advances in the development of new high-performance polyamide formulations and applications.

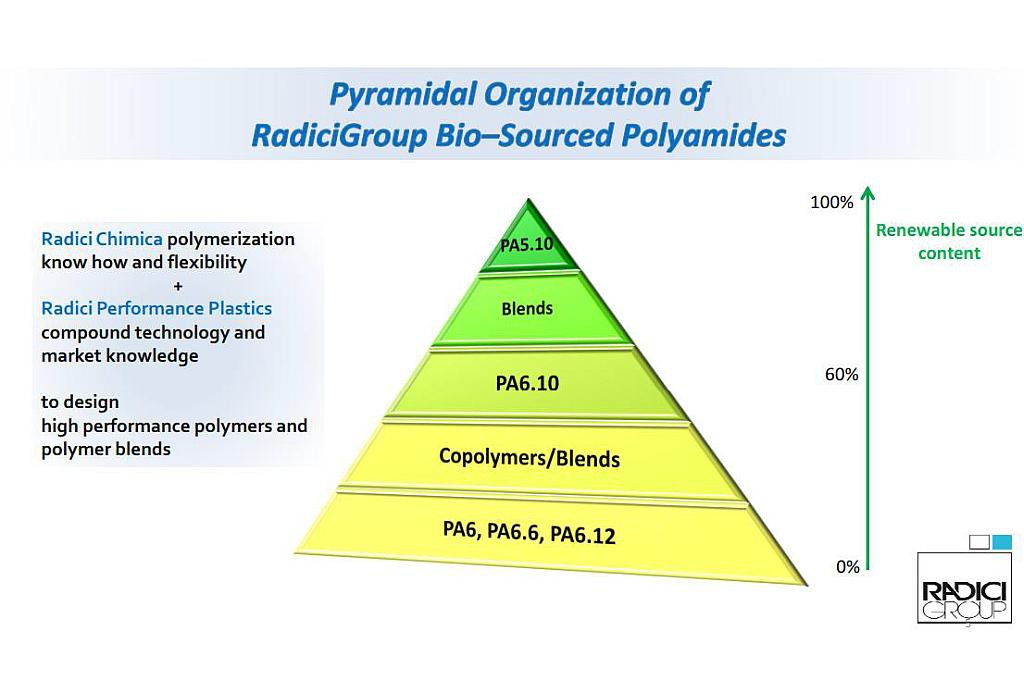

More specifically, the two RadiciGroup specialists focus on PA 6.10, PA 6.12 and PA 5.10 long-chain polyamides, which not only meet the market’s high technical performance needs, but also satisfy the growing demand for products obtained from total or partial biological source materials.

“Some of the products are totally new for RadiciGroup, while others have been in our portfolio for some time,” Erico Spini said. ”However, the most important aspect we want to stress is that market demand is shifting towards new niche products and that RadiciGroup is ready to satisfy any specific customer request. We’ve also developed a number of solutions for the automotive sector, the most demanding industry from the point of view of technical performance. Our solutions meet the need for both technical and sustainability performance.”

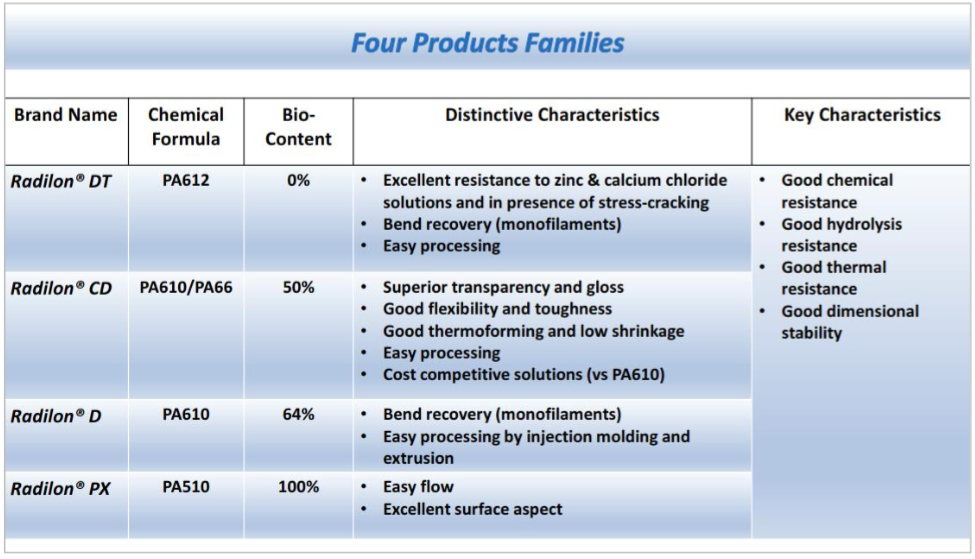

Indeed, RadiciGroup Performance Plastics has widened its Radilon® product range by adding a number of PA 6.10 (Radilon® D), PA 6.10/6.6 (Radilon® CD) and PA 6.12 (Radilon® DT) products, which are ideal for fuel, air or oil systems and feature excellent mechanical properties, excellent processability, low water absorption and good dimensional stability. Compared to traditional PA 6 and PA 6.6, these new polyamides also boast higher chemical resistance, a crucial property for certain automotive applications, as well as other uses.

Indeed, RadiciGroup Performance Plastics has widened its Radilon® product range by adding a number of PA 6.10 (Radilon® D), PA 6.10/6.6 (Radilon® CD) and PA 6.12 (Radilon® DT) products, which are ideal for fuel, air or oil systems and feature excellent mechanical properties, excellent processability, low water absorption and good dimensional stability. Compared to traditional PA 6 and PA 6.6, these new polyamides also boast higher chemical resistance, a crucial property for certain automotive applications, as well as other uses.

Moreover, RadiciGroup Performance Plastics is presently working on a prospective non- automotive field of application for these LPCA products: water management. Changes in the governing laws already place (or will place in the future) restrictions on the use of conventional polyamides. Excellent hydrolysis resistance, lower moisture absorption and superior processability make the LPCAs the ideal solution compared to other products already on the market.

Last, but not least, is the extrusion market. For this kind of applications, RadiciGroup has developed and obtained the required approval for Radilon® DT22, a PA 6.12 product, whose excellent processabiliy, elastic recovery and chemical resistance make it ideal for personal care applications (bristles for toothbrushes and mascara brushes). DT 22 was also developed to offer an intrinsic competitive advantage: improved abrasion resistance.

Last, but not least, is the extrusion market. For this kind of applications, RadiciGroup has developed and obtained the required approval for Radilon® DT22, a PA 6.12 product, whose excellent processabiliy, elastic recovery and chemical resistance make it ideal for personal care applications (bristles for toothbrushes and mascara brushes). DT 22 was also developed to offer an intrinsic competitive advantage: improved abrasion resistance.

PA 6.10’s special chemical resistance and elastic recovery properties, as well as its resulting increased durability, make it a commonly used material for the production of monofilament for industrial applications, such as paper mill equipment. A specifically formulated version of this PA, featuring high intrinsic burst resistance, can also be used for the manufacture of fuel system pipes.

“The intrinsic properties of LPCAs, which are combined with a specific formulation during the polymerization stage, give us the capability to satisfy an increasingly greater number of customer requirements,” Nicolangelo Peduto noted. “Our know-how of the polymerization process upstream of the production chain, together with our compounding technology downstream, is a powerful competitive advantage enabling us to keep pace with the trends of the market, which is always in search of products featuring ever higher performance.”

Source

RadiciGroup, press release, 2017-06-07.

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals