Dear reader,

Dear reader,

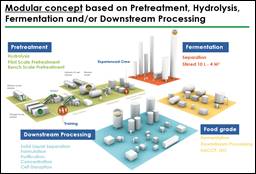

BPF, the Bioprocess Pilot Facility (based in Delft, the Netherlands), celebrates its 5th anniversary on 31st of May. Right after the start in 2012 the existing pilot plant has been upgraded and expanded with a dedicated pre-treatment facility and food plant covering fermentation and downstream processing. In March 2015 the BPF officially opened and all piloting modules are fully operational since then. Multiple international customers have already made use of our piloting facilities.

Organisational change

Organisational change

Eric Goossens joined BPF in April as managing director. He is the successor of Hans van Leeuwen who retired in December 2016. Eric is an executive with over 25 years of experience with profound experience in general management, operations management, technology transfer, project management and change management. He brings his experience from large and medium sized (international) industrial and R&D companies in the areas of biotechnology, (bio)pharmaceutical and (petro)chemical. Eric has Master degrees in Chemistry and Process Engineering as well as business school training from INSEAD and IMD.

Demo plant operation at BPF

DSM and BPF have installed a demo plant in close collaboration, which was officially opened in Q1 2017. The aim of the project is to get more value from Canola (Rapeseed) by separating the proteins and make these suitable for human consumption. The demo plant is used to learn more about continuous operation for scale up to the commercial plant and is also used to make commercial samples for the potential customers of DSM. The demo plant will be operated 24 hours per day by the staff of BPF.

Potential expansion of pilot plant

BPF is considering to expand the pilot plant with a 8m3 bubble column fermentor. The basic design has been completed and we are looking for additional market input to customize the fermentor. Which functional requirements would be relevant for you in order to be interested in making use of this fermentor expansion at BPF? We are looking forward to your feedback.

Just a reminder of what we do at BPF:

an open access facility where companies can scale up new sustainable production processes by converting bio-based residues into useful chemicals or fuels for Food, Chemical industry and Pharma longstanding track record of validating and scaling up lab based biotech concepts, focus on biomass Pretreatment, Hydrolysis, Fermentation and Downstream Processing examples of collaboration partners are Verdezyne, DSM, Corbion, Evonik and many more.

Kind regards

Arno van de Kant (cell +31 642480754, arno.kant-van-de@bpf.eu)

Peter Flippo (cell +31 6 28239173, peter.flippo@bpf.eu)

Source

Bioprocess Pilot Facility, press release, 2017-06-09.

Supplier

Bioprocess Pilot Facility BV (BPF)

DSM

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals