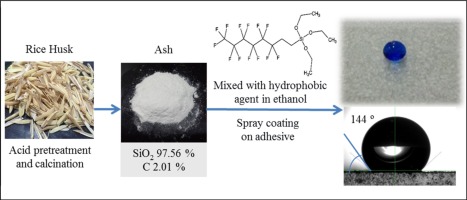

- Calcination of citric acid washed RH produce high purity amorphous silica.

- HFDS modified RHA exhibit near superhydrophobic with antifouling ability.

- Particle agglomeration negatively affects SA modified RHA antifouling ability.

Abstract

Superhydrophobic coating has been widely studied due to its water repellent, antifouling, self-cleaning and weather protective properties. For better sustainability, rice husk ash was studied in this work to substitute the use of commercial nanoparticles in superhydrophobic coating. The rice husk ash contains 97.5 wt.% of SiO2 and 2.0 wt.% of carbon after pre-treatment using citric acid and calcination at 800 °C for 0.5 h. The BET surface of irregular ash particles was measured to be 206.03 m2 g−1 and the average pore diameter is estimated at 5.7 nm. The near superhydrophobic coating could be formed easily by spraying the mixture of ash (6 wt.%) and a hydrophobic agent in ethanol solution on a thin layer of commercial adhesive. FTIR spectra could not confirm the existence of CF2 group on coating when 1H,1H,2H,2H-perfluorodecyltriethoxysilane (HFDS) was added as the hydrophobic agent in the coating formulation. The other hydrophobic groups on the coating could not be confirmed when stearic acid was added into the coating formulation due to the interference of adhesive layer. Still, the average water contact angle on the ash/HFDS coating (3M-HFDS) was improved to 144.2°. However, slight decrement in hydrophobicity was observed when stearic acid grafting groups was introduced. The near superhydrophobic coatings showed antifouling properties when they were immersed in the slurry solution containing kaolin.

Graphical abstract

Source

Progress in Organic Coatings, 2016-06.

Supplier

Progress in Organic Coatings - Journal

University Sains Malaysia (USM)

University Teknologi MARA (UiTM)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals