Together with the European Space Agency (ESA), Bcomp Ltd has developed the first natural fibre reinforced satellite panel. The aim to make space exploration cleaner and safer, thanks to the unique versatility of Bcomp’s award-winning sustainable lightweighting technologies. The panel is a JEC Innovation Awards 2020 finalist in the Aerospace category.

The project is the result of a close collaboration between Bcomp Ltd and experts from the European Space Agency, RUAG Space and IRS Stuttgart, funded under the ESA General Support Technology Program.

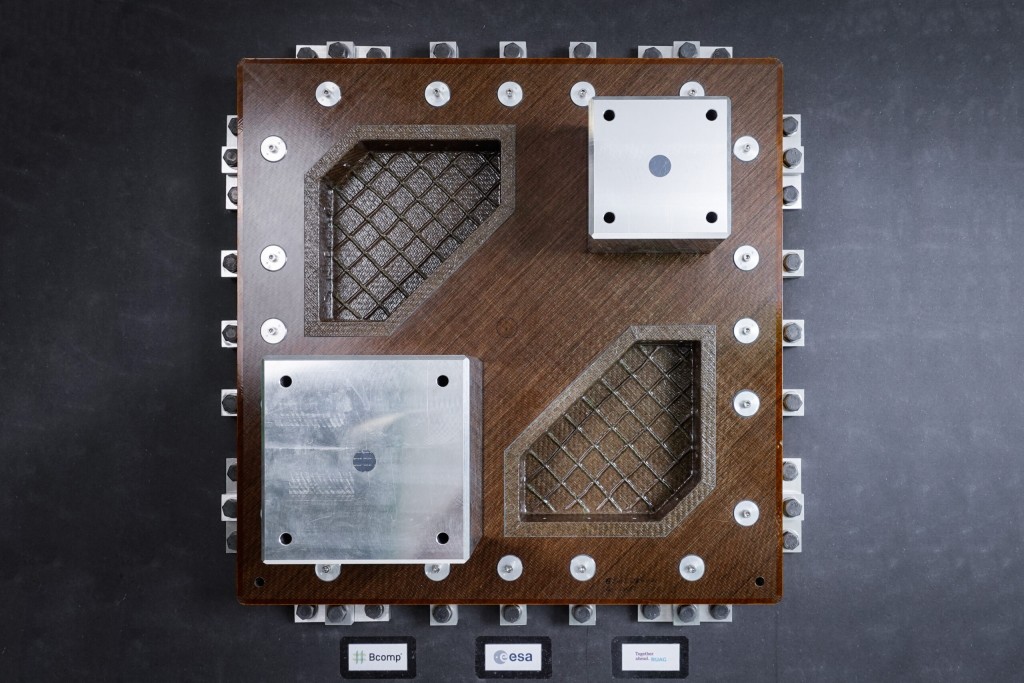

The bio-composite satellite structure panel has been developed within the framework of ESA Clean Space Initiative. It demonstrates the exceptional versatility of Bcomp’s proprietary powerRibs™ and ampliTex™ natural fibre technologies, even in the most extreme environments.

Improving safety

According to the ESA, what goes up must come down, except in space. Bio-composites create new opportunities for “Design for Demise“ – the intentional design of the space system hardware, such that it will completely burn up upon re-entry at the end of its mission. This makes it safer for humans, ground infrastructure and the environment. Such a design, allowing disposal by controlled re-entry, is often mandatory under ESA’s Space Debris Mitigation requirements.

Specifically, demisable windows were designed into the demonstrator panel, thus creating targeted plasma entry points, without compromising the panel’s stiffness thanks to the powerRibs™ reinforcement.

Tested for space

Not only improving safety, the bio-composite satellite panel meets the requirements across a wide range of temperatures. It also has sufficient strength to carry sensitive equipment under the heavy loads encountered during a rocket launch. In addition, vibration damping is significantly improved vs. a standard all-aluminium panel thanks to the viscoelastic behaviour of natural fibres.

An extended test campaign verified high resistance to intense UV radiation and to mechanical- and thermal cycling fatigue. The remarkably low thermal expansion of natural fibres makes it highly compatible with carbon fibre reinforced polymer structures for extra strength.

High potential for the future

In a Space Industry growing faster by the day, the shift towards cost-efficient, low impact and highly demisable materials must happen quickly. Bcomp’s powerRibs™ and ampliTex™ solutions are cost-efficient, has low environmental impact, and are highly demisable and versatile bio-composite technologies. The technologies are not limited to spacecraft secondary structures, but can potentially apply to radomes, antennae or even launcher structures.

About the European Space Agency (ESA)

In the frame of the General Support Technology Programme (GSTP), the European space industry develops leading edge space technologies that enable missions to discover the Universe, understand our environment, navigate, educate and save lives. It’s one of the best instruments in ESA to help assure Europe’s competitiveness in the global market, creating jobs and keeping Europe at the forefront of technological innovation.

About RUAG Space

RUAG Space is the leading supplier of products for the space industry in Europe and RUAG Space specializes in components for use aboard satellites and launch vehicles.

About IRS

The Institute of Space Systems is specialised in research and teaching space technology and space applications, fom aerothermodynamics to small satellites to dust astronomy.

Source

Bcomp, press release, 2020-10-13.

Supplier

Bcomp Ltd.

European Space Agency (ESA)

Institute of Space Systems IRS (DLR)

RUAG Space

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals