Natur-Tec, a business unit of Northern Technologies International Corporation (Nasdaq: NTIC), and NatureWorks introduced today a jointly developed technology platform that lowers the cost of compostable serviceware while increasing its performance. The new technology platform – formulations based on low carbon footprint Ingeo™ biopolymer – produces heat resistant serviceware with rigidity approaching that of injection molded polystyrene and higher toughness than either polypropylene (PP) or polystyrene (PS) cutlery.

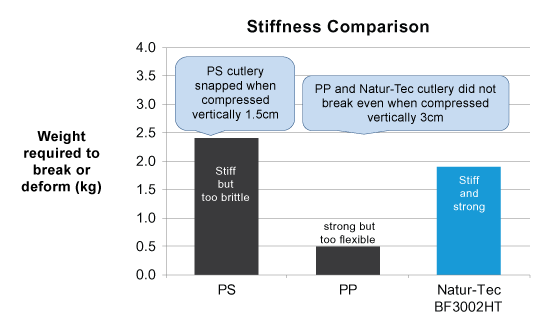

Compostable cutlery made using the new formulation was benchmarked against standard PS and PP cutlery sold in the market using practical tests designed to mimic the actual conditions of cutlery in use. These tests compared three parameters: rigidity, toughness (the amount of energy required to make the implements break), and heat resistance.

FIGURE 1

Figure 1 compares the stiffness of cutlery made from the new formulation with PS and PP cutlery. PS cutlery is typically stiff but too brittle, while PP cutlery is typically strong yet too flexible. In contrast, the new Natur-Tec formulation is both stiff and strong.

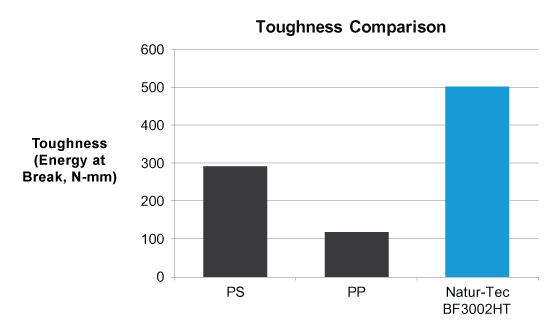

FIGURE 2

Figure 2 demonstrates the new formulation’s higher toughness (requiring more energy to break) than both PS and PP.

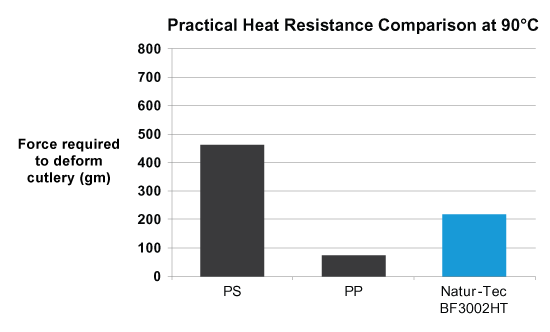

FIGURE 3

Figure 3 indicates that in heat resistance testing the force required to deform the new Ingeo-based formulation cutlery at 190° F (90°C) is more than PP but less than PS. At a maximum compression load of 200 grams (~ ½ lb.), however, the new formulation exceeds the toughness requirements for most, if not all, serviceware applications.

FIGURE 4

Figure 4 shows the substantial deformation on handle and bowl of the PS spoon, right, compared to the pristine shape of the Ingeo-based spoon, left, after both were compressed in hot water.

For injection molders, the new technology platform also addresses a processing issue common to prior compostable cutlery products – warpage of the cutlery during cooling and crystallization, which can reduce overall yield and so increase the per-piece cost. “Following field trials, injection molders relayed to us that scrap from finished part warpage and inconsistency in material flow, which could be up to 20 percent, is now minimal, and less than 5 percent, when our new technology platform is used,” said Vineet Dalal, Vice President and Director of Global Market Development for Natur-Tec.

Natur-Tec and NatureWorks collaborated on development for more than a year and will jointly market the technology as a two-part resin platform that combines in one package (named BF3002HT) a nucleated impact modified Ingeo-based masterbatch with one of NatureWorks latest Ingeo performance grades. The two-part Ingeo-based platform helps retain polymer properties and so provides better mechanical performance as compared to filled-PLA compounds. Natur-Tec will lead BF3002HT sales and marketing efforts. The new technology platform is fully approved for food contact and is now in final testing for compostability certification.

Natur-Tec will also manufacture serviceware for companies interested in test marketing cutlery before beginning in-house injection molding. Natur-Tec personnel are available to work with customers on applications other than serviceware, as this new technology platform can be tailored to many different types of compostable injection molded products, including disposable coffee filter cups and agricultural trellis clips, and non-food contact applications.

Contact

email info@natur-tec.com

call +1 763 404 8700

About Northern Technologies International Corporation

Northern Technologies International Corporation develops and markets proprietary environmentally beneficial products and technical services either directly or via a network of subsidiaries, joint ventures, and independent distributors in over 50 countries. NTIC’s Natur-Tec® branded products are engineered using proprietary blends of biodegradable polymers and natural materials to create biobased (renewable resource based) and certified compostable plastics. The broad Natur-Tec bioplastics portfolio spans flexible film, foam, rigid injection molded materials, and engineered plastics. By using Natur-Tec products as an alternative to conventional plastics, industry and consumers reduce their carbon footprint and move towards a zero carbon or carbon neutral footprint. It also provides for environmentally responsible and sustainable end-of-life solutions.

About NatureWorks

NatureWorks LLC is a company dedicated to meeting the world’s needs today without compromising the earth’s ability to meet the needs of tomorrow. Today, NatureWorks is a world leading biopolymers supplier and innovator with its Ingeo portfolio of naturally advanced materials made from renewable, abundant feedstocks with performance and economics that compete with oil-based intermediates, plastics, and fibers, and provide brand owners new cradle-to-cradle options after the use of their products. NatureWorks is jointly owned by Thailand’s largest chemical producer, PTT Global Chemical, and Cargill, which provides food, agriculture, financial and industrial products and services to the world.

Source

NatureWorks, press release, 2016-10-18.

Supplier

Natur-Tec India Private Limited

NatureWorks LLC

Northern Technologies International Corporation (NTIC)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals