The Green Refinery project is the first example in the world of conversion of a conventional refinery into a biorefinery.

The Green Refinery project is the first example in the world of conversion of a conventional refinery into a biorefinery.

At a difficult time for the European refining industry, eni identified the opportunity to reuse the catalytic hydrodesulfurization section in the Venice refinery, reconfiguring it into a biorefinery. Inside the detected configuration, it was utilised the proprietary EcofiningTM technology, previously developed by eni in the laboratories of San Donato Milanese in partnership with Honeywell-UOP.

Following the conversion, the biorefinery will be able to produce high-grade biofuels – in particular green diesel, but also green naphtha, LPG and potentially even jet fuel – from raw materials of biological origin, to meet the requirements of the EU Directive on renewable energy and derive 10% of energy in conventional fuels from renewables by 2020.

With the start up of the Green Refinery, eni will be able to produce around 300,000 tonnes per year of green diesel already in 2014. The feedstock will initially be palm oil; in the second phase, also animal fats, used oil, oils from algae and various types of biological waste.

The EU directive1 on renewable energy, also known as RED 20-20-20, provides member states with significant targets to be reached by 2020.

- a 20% reduction in greenhouse gas emissions (GHG – Greenhouse gases: CO2, CH4, N2O, etc.) compared with 1990 levels;

- a 20% reduction in energy consumption compared with the projections for 2020;

- 20% of energy production from renewable sources, with a level of 10% (on an energy basis) of renewable and sustainable biofuels for road transport.

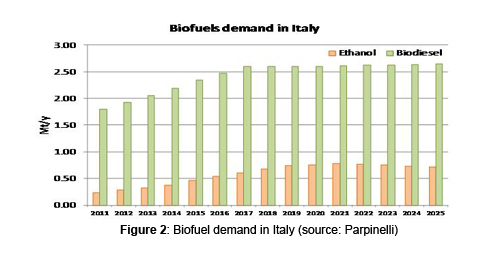

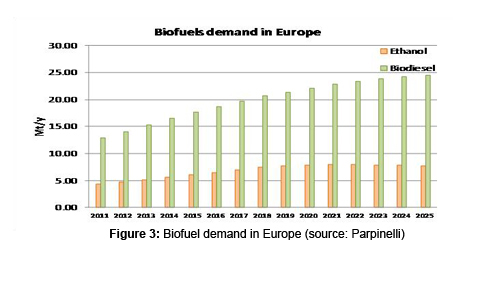

In 2011 biofuel consumption in Italy reached 2 million tonnes, mainly imported from EU countries. Demand in both Italy and the EU is still rising and, in particular, consumption of biodiesel2 is expected to grow until 2020.

While adding bioethanol3 and biodiesel to traditional fuels is the simplest and most immediate way of responding to regulatory provisions, the quality of such products is quite poor when compared to conventional fuels, making their use problematic. For biodiesel in particular the disadvantages are related to low levels of chemical stability, inadequate cold reactions, fouling and low levels of energy content per unit of energy. Many car manufacturers now advise against the use of biodiesel in their engines. The maximum proportion of biodiesel that can be added to conventional fuels without causing severe engine problems is currently around 7%.

Current regulations (Fuel Quality Directive4 – FQD) also foresee a minimum reduction of 6% of greenhouse gas emissions compared with fossil fuels, a target that is unreachable only through the use of biodiesel.

It is consequently necessary to develop new fuel biocomponents that could substitute biodiesel, at least in part, and improve engine efficiency while reducing emissions. The solution proposed by eni is Green Diesel, produced using the proprietary EcofiningTM technology, which is able to meet these requirements.

Eni’s Strategy

The Green Refinery project aims to reconfigure the facilities at the Venice Refinery by identifing innovative solutions for the conversion of the current installed operating capacity, based on traditional production cycles, to “green” cycles that are sustainable both from environmental and economic perspective.

In particular, it has been developed a business model which, through the enhancement of existing plants and proprietary eni technologies, will make possible the conversion of low-cost non-conventional biological feedstock (such as vegetable oil, biomass, etc.) into high-value products (green diesel, green LPG, green naphtha, etc.). The model is particularly interesting considering the forecasts on the rising demand for biofuels in Italy.

The process is based on the innovative EcofiningTM technology, developed by eni and tested in its laboratories, which makes it possible to produce high quality sustainable biofuels, that overcome the limits of current FAMEs (Fatty Acid Methyl Esters) while reducing particulate emissions and improving engine efficiency, in line with current legislation and EU directives.

The raw materials of biological origin used in the process are divided between first generation feedstock (vegetable oils in competition with the food chain), second generation (animal fats, used oils and agricultural waste) and third generation (oils from algae or waste).

EcofiningTM is also able to use second and third generation feedstock, anticipating possible regulation updates.

Detailed technological studies and feasibility demonstrated that it is entirely possible to convert a traditional oil refinery into a bio-refinery with reasonable levels of investment. In particular, due to the its structure, the Venice refinery is considered especially suitable for conversion.

Eni’s Technology

For the conversion of a conventional refinery into a biorefinery. in compliance with thecurrent regulations while also producing biocomponents for high grade fuels, eni will use the proprietary EcofiningTM technology, developed by eni and HoneyWell-UOP, which can produce Green Diesel.

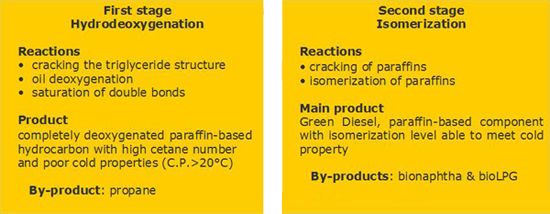

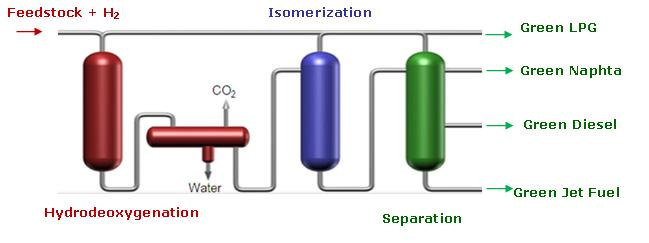

EcofiningTM is essentially a two-stage process:

- during the first stage of hydrodeoxygenation of vegetable oil, the oil, or more generally the biological feedswtock, is transformed into a blend of linear C16-C18 paraffins;

- in the second isomerization stage, the paraffin isomers are transformed to give the product the necessary cold properties and meet the specifications of diesel fuel.

The final product, known as HVO (Hydrotreated Vegetable Oil) or Green Diesel, is a very high-quality diesel, with excellent cetane levels (cetane number1>70, similar to top quality diesel obtained from Gas-to-Liquidsprocesses), with high calorific value that does not contain aromatics or heteroatoms (sulphur, nitrogen, oxygen). The product is also immiscible with water and is entirely compatible with diesel produced from petroleum (to which it can be added up to 30%), guaranteeing that the fuel obtained respects the strictest regulations and has the best performance levels for both engines and the environment.

The high calorific value of Green Diesel will allow to reduce the consumption of the vegetable feedstock (initially palm oil, certified to European standards) compared with traditional processes and to use, in the near future, second and third generation feedstock, as animal fats, used oil, agricultural waste, oil from algae and other biological waste.

More information about the sustainability of the EcofiningTM technology in Green Refinery Project.

Benefits

The availability of the proprietary EcofiningTM technology ensures than eni can convert its Venice conventional refinery into an innovative biorefinery for the production of high grade fuel in compliance with current legislation and EU directives. In the current European refining context, in which nine refineries have been closed in recent years, the Venice Refinery, which would otherwise be closed down, will be kept in production thanks to the Green Refinery Project that will give the plant a new life using a new high-tech processing cycle.

The solution identified by Eni for the conversion of existing units generates an additional benefit in terms of lower investment cost, compared with the construction of a new plant. To obtain the volume of biofuel required by the refining & marketing division portfolio, according to the provisions of the directive on renewable energy, the Green Refinery project will require an investment of around €100 million, compared with the €600 million that would be needed for a new EcofiningTM plant. The integration with existing plant will significantly reduce the project’s investments costs and provide a high level of return already in the first years of operation.

An additional advantage will be a substantial reduction in emissions from the industrial plant at the Venice facility, with beneficial effects for the environment. In particular, when fully operational, there will be:

- a reduction of more than 45% wt in the emissions of NOx;

- a fall of 65% wt of SOx emissions, that can also be reduced to zero with the recovery of the H2S produced and its recycling in the reaction section;

- a reduction of 32% wt in the emissions of particulate.

Green Fleet

A Green Diesel-based biofuel was successfully tested on the Italian Navy offshore patrol vessel Foscari, which became the first ship of the Flotta Verde (Green Fleet).

A Green Diesel-based biofuel was successfully tested on the Italian Navy offshore patrol vessel Foscari, which became the first ship of the Flotta Verde (Green Fleet).

The test represents the final phase of a research project, called Flotta Verde (Green Fleet), between the Italian Navy, the Naval Armaments General Directorate and the Research and Technological Development unit of eni’s Refining & Marketing Division. The project was born to find an alternative product (specifically a biofuel composed by at least 50% Green Diesel) to the marine fossil fuel used by the Navy ships.

Thanks to the commitment and cooperation between the Navy’s naval engineers and eni’s chemical engineers, the Green Diesel was produced through the EcofiningTM technology, developed by Eni in partnership with Honeywell-UOP.

The initial phase of development for the fuel optimal formulation was conducted through a series of laboratory and engine bench test, using the facilities of the eni’s research center in San Donato Milanese; later the most suitable formulation was found and tested at the emission testing facilities.

For the Navyhigh percentage (more than 50%) of Green Diesel in the biofuel, the experiment was an excellent result. The Italian Navy is at the forefront in Europe as the first navy operationally testing Green Diesel, anticipating the European deadline, which includes the use of 10% organic fraction by 2020.

For the Navyhigh percentage (more than 50%) of Green Diesel in the biofuel, the experiment was an excellent result. The Italian Navy is at the forefront in Europe as the first navy operationally testing Green Diesel, anticipating the European deadline, which includes the use of 10% organic fraction by 2020.

According to the Navy official statement, the transition from one fuel to another did not change performance and thermodynamic parameters of the propulsion motors; also CO2 and pollutant emissions were reduced in line with expectations.

Production of Green Diesel will start in eni’s Venice biorefinery from spring 2014.

1Renewable Energy Directive (RED) – 2009/28/CE

2Biodiesel is a fuel obtained from renewable sources (vegetable oil and/or animal fat ) using a chemical process; for its chemico-physical properties, it can partially be mixed with diesel derived from petroleum.

3Bioethanol is ethanol (CH3CH2OH) produced from biomass by a fermentation process.

4Fuel Quality Directive (FQD) – 1998/70/CE

More Information

Ecofining & Green Diesel (PDF)

Source

Eni, press release, 2014-03-05.

Supplier

Eni S.p.A.

European Union

Honeywell

UOP

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals