Polymer materials that regulate the relative humidity in their environment are relevant for applications in the packaging and building sectors. The shelf life and quality of these products are dependent, among other factors, on their water activity. Spoilage of the packed product may be caused by water vapour absorption or by desorption of already bound water, leading to problems such as the loss of crispiness of snack products and microbial growth. On the other hand, products with a high water content may become dry and change their textural properties. In buildings, too, humidity is important to control interior relative humidity levels and to avoid mould growth.

Many salts and salt solutions absorb and desorb high amounts of water vapour from and to their environment. Therefore, salts and salt solutions are able to regulate the relative humidity in their environment in a specific range, depending on the actual salt substance. While polymer matrices are suitable carriers for salts, a challenge is the immobilization of salt solution, which forms during water vapour absorption. The answer is to create cavities inside the polymers matrix to store the salt solution, which is achieved by foaming or by stretching filled polymers such as polypropylene (PP) with dispersed calcium carbonate particles or with sodium chloride particles (NaCl), which has been shown to induce the formation of cavities.

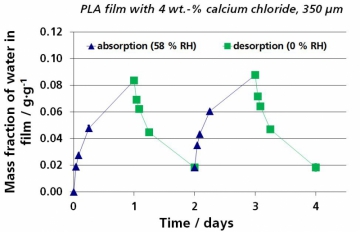

Now, a group of researchers from Fraunhofer Institute for Process Engineering and Packaging IVV and Technical University Munich have published a study in which 2 and 4 wt.-% calcium chloride crystals were dispersed in PLA and PP. These materials were subsequently used to produce films, which were biaxially stretched to induce the formation of cavities. These cavities would capture and immobilise the calcium chloride solution formed from calcium chloride crystals during water vapour absorption.

The researchers found that these films absorbed 15 wt.-% water vapour at 75 % relative humidity. PLA films with calcium chloride absorbed and desorbed water vapour 10-times faster than PP films with calcium chloride. The reason is the 100-times larger value for the water vapour permeation coefficient of PLA compared to PP.

Currently, Fraunhofer IVV is seeking academic and industrial partners to bring the technology to a higher technology readiness level which is currently TRL 4 to 5. An issue will be also to use plants and processes which allow the processing of the potentially corrosive calcium chloride.

Source: Journal of Applied Polymer Science, Volume 2017

Source

Bioplastics MAGAZINE, 2017-09-20.

Supplier

Fraunhofer-Institut für Verfahrenstechnik und Verpackung (IVV)

Technische Universität München (TUM)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals