As odd as it might sound, recycling of clothes is not well developed. Only a small portion of our clothes and textiles end up being reused or recycled, mostly via donations. The majority of our clothes end up in the trash and are incinerated with regular mixed waste.

To solve this problem, the clothing industry needs a complete set of digitalization tools. It starts with shopping methods that help you buy the right fit, thus avoiding purchases that end up in the closet and are never worn. In the end of the lifecycle, you need different ways of recycling or reusing the materials. This new circular ecosystem needs to digitalize the whole infrastructure: manufacturing, buying, collection, sorting, recycling, and utilization of fibre materials.

3D Body Scanner For On-Demand Shopper

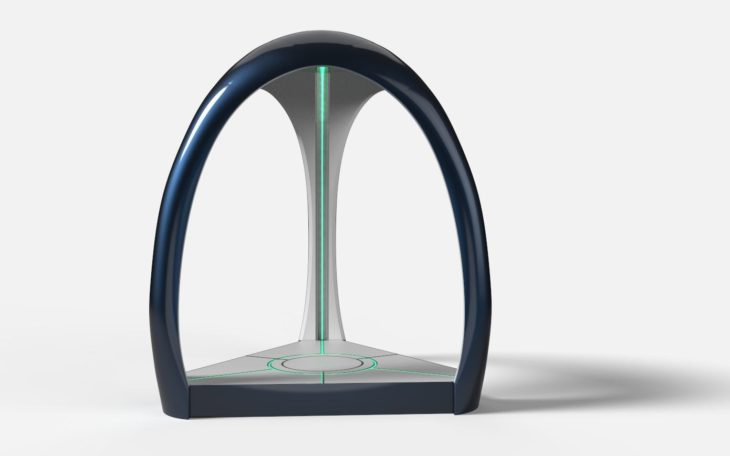

One of the new digital solutions offered to the textile industries is a full-body 3D scanner and its diverse user applications that was developed by a Finnish startup, NOMO Technologies.

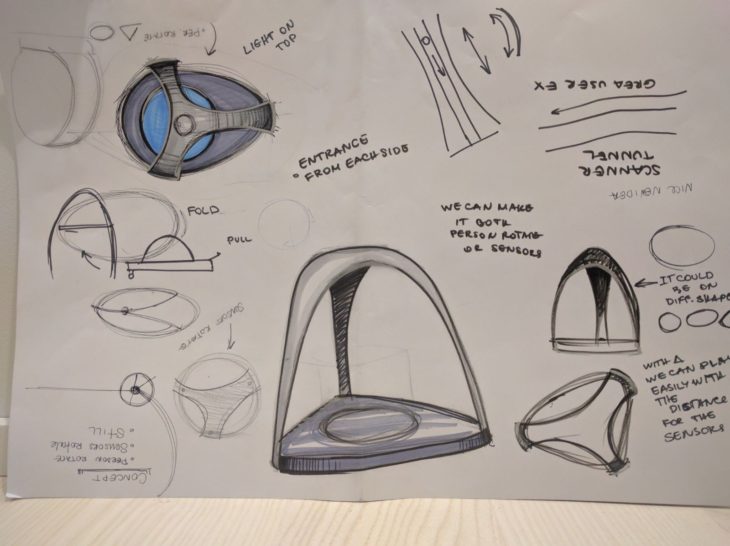

The scanner looks and works like a device from a science fiction movie: You stand on a platform’s rotating table with the 3D camera sensors surrounding you. The end result is a full 360-degree model of your body, uploaded to a cloud service. Johan Wirta, one of the founders of NOMO, has a vision that their solution will have great environmental impact and will be more than just a great help for online shoppers.

“NOMO has massive potential in decreasing both textile waste and unnecessary shipping when consumers shop online. Clothing companies gain important information about the real sizes of consumers in different countries and have thereby better opportunities to manufacture clothes with the right measurements for each market and to reduce unnecessary surplus,” says Wirta.

“Half of the product returns in the 130-billion-dollar online clothing business happen because people order multiple sizes to try them on at home and end up returning most of them,” he continues.

NOMO has worked with VTT since 2015, developing different sensors with the right kind of setup, software, and algorithms. Now NOMO is participating in a VTT coordinated DICI project to pilot the project inside the textile industry. A production model of their system should be available in the fall of 2017.

“We knew VTT had the 3D modeling know-how, and with its help we created the first applicable prototype of our next generation full-body 3D scanner in spring 2017,” says Wirta.

Traditional Recycling Is Not Enough

Inventions like NOMO will help people to buy less, thus reducing waste and making the textile industry and shopping in general more sustainable. 3D scanning would help to create an on-demand economy, where products are only being made after people order them online. Retail stores would not have excess stock, but only a limited selection of models available.

Hand drawn draft 360 body scanner

3D scanning would help to create an on-demand economy, where products are only being made after people order them online.

NOMO is a great example of digitalization, but there are more problems to be solved at the end of the product life. VTT’s Research Professor Ali Harlin explains:

“There have been multiple projects to try out different textile recycling systems. Adding more recycling bins to households will not work for two reasons: there are already too many bins, and separating different textile fibres is difficult even for experts in the textile industry.”

In order to turn textiles into raw materials, different fibres need to be separated reliably. To avoid the “garbage in, garbage out” type scenario, you need machine vision, robotics, and artificial intelligence to do the separating before the materials can be processed further. With current mostly human-powered sorting technologies, 90 percent of recycled textile materials are incarnated as fuel and only 10 percent are being reused.

Artificial Intelligence Will Help the Recycling Ecosystem

Another Finnish company, Remeo, is aiming to solve this problem. Finland alone produces 70,000 tonnes of used textiles and only one-fifth of it is being recycled. Petteri Asikainen, Process Engineer at Remeo, explains why this has to change in order to make recycling more profitable.

“If humans sort the textiles, it takes a lot of manpower. With machines, you get both the volume and higher accuracy. Both of these qualities are needed when you try to scale up these processes and build systems that provide considerable advantages compared to current technology,” says Asikainen.

Remeo’s goal is to apply a machine vision system to recognize different fabrics, using similar technologies that VTT has helped to build for other waste processing plants. After receiving information from the near-infrared, RGB, and 3D cameras, the artificial intelligence helps the picking system to sort cotton from polyester or viscose. This type of technology would revolutionize the way we collect recyclable textiles because, for example, you could reuse clothes that are torn and dirty as raw material. It would ramp up the volume available for recycled components, consequently paving the way for new business opportunities.

VTT Is Modeling the Future of Textile Ecosystem

This is why Remeo as a company is participating in the Telaketju project with various Finnish stakeholders and funders in order to create a circular ecosystem for textiles. The ecosystem is based on a distributed operation with shared quality standards for defined applications and viable solutions for sorting. Within the project, VTT is modeling the future ecosystem for textile industry. All aspects of the much-needed digitalization are covered, from materials to supply chains to recycling. The goal is to reduce waste in general in the end. As Satu-Marja Mäkelä, a Project Manager at VTT, describes:

“Our greatest goal is to reduce the amount of textile production in general by creating better digital tools for on-demand production and supply chain management, creating a true on-demand economy around it. When we get the whole industry to participate, we can create a sustainable circular economy system.”

Contacts

Research Professor Ali Harlin

tel.: +358405332179

email: ali.harlin@vtt.fi

Project Manager Satu-Marja Mäkelä

tel.: +358408481229

email: satu-marja.makela@vtt.fi

Author

Pekka Pekkala

Source

Supplier

Nomo Technologies

Remeo (FI)

Technical Research Centre of Finland (VTT)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals