Blue Marble Biomaterials, a wholly owned subsidiary of Blue Marble Energy Corp., has launched the first zero-waste chemical biorefinery in the US in Missoula, Montana. Blue Marble Energy uses novel bacterial consortia to produce specialty biochemicals from the anaerobic fermentation of a range of biomass feedstocks. (Earlier post.) The facility will produce 72 tons of fine chemicals a year and only purified water and pellet fuel for wood-boilers as its waste.

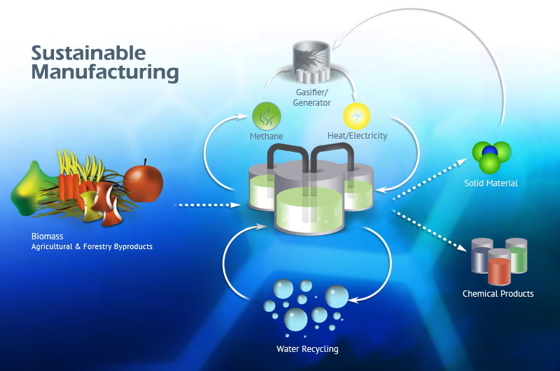

The company is implementing novel recycling systems to eliminate waste and reduce cost: a photo-bioreactor containing algae purifies wastewater and waste gas from the fermentation system and their solid waste is dried and pelletized for use in wood-burning furnaces and stoves. The company has future plans to power its facilities using its own waste gas and pelletized solid waste in already on-site gasifiers.

Blue Marble Energy’s proprietary AGATE (Acid, Gas and Ammonia Targeted Extraction) system uses different bacterial consortia (“cassettes”) in an anaerobic fermentation process to produce carboxylic acids, esters, mercaptains / thiols, and terpenes. The system is feedstock flexible; for the Missoula plant, Blue Marble is using waste coffee grounds and spent grain from a major brewer, said Kelly Ogilvie, Blue Marble’s CEO.

(Blue Marble uses a supercritical fluid extraction process to remove the remaining lipids from the coffee grounds.)

The feedstock flexibility can manifest as price stability for Blue Marble’s chemical customers, Ogilvie noted. For example, the company has a stable price on the spent grain from the brewer; a waste product which otherwise would end up in landfills (i.e., the amounts above that which could economically be used for cattle feed, the other major disposal pathway for spent grain).

If we have fixed feedstock (such as the waste spent grain), we have price stability. We can hedge off the future price volatility of petroleum. Price protection is a huge issue right now. – Kelly Ogilvie

The start-up of the Missoula biorefinery comes on the heels of President Obama’s announcement on 24 June to invest $500 million in US-based advanced manufacturing through the Advanced Manufacturing Program (AMP). (Earlier post.) Blue Marble founders, Kelly Ogilvie and James Stephens were members of the council that informed the decision to proceed with the President’s Advanced Manufacturing Program.

One of the purposes of PCAST (President’s Council of Advisors on Science and Technology) was for us to sit next to Proctor & Gamble. “P&G, you guys are huge, you use biobased stuff, you have scale. Blue Marble, you’re good at technology but not at scale. How do we partner companies like you two for leverage?”

In the aftermath of the recession, all these larger companies were reining in R&D spending. The question is, if we are reining in spending because consumers are, how do we continue to innovate? That comes through partner building, partnering between small companies and big. But how do we create a situation where small companies are not afraid to get in bed with the big guys because they might get crushed?

…This is the biggest game ever. The future biorefineries are going to be replacing that which has no replacement right now: petroleum. Everyone is trying to find these solutions. It’s an uneasy relationship right now between bio-based and petrochemical companies. We don’t operate, or produce at a price that competes with petroleum on a reasonable basis right now. But maybe at scale, they switch out.

At some point, you see industrial players creating new verticals in the market. At some level of scale, we start to be able to talk about competing with petroleum. This is also about keeping jobs in the US. One of the conversations was about how we leverage what the US has in abundance: resources – agricultural residue, forests, biomass from a variety of sectors. The way you keep jobs here is by focusing on monetizing the biomass.

The US is the Saudi Arabia of biomass. If we can figure out how to leverage biomass into products, we’re talking about exporting products and importing money, instead of the other way around. Everybody sees what this can become. AMP is a $500-million baby step towards creating an advanced manufacturing sector in the country. – Kelly Ogilvie

Blue Marble is in several Memoranda of Understanding with clients, including global chemical distributor Sigma-Aldrich, to bring bio-based chemicals to the global market.

A general diagram of Blue Marble’s manufacturing system. A photobioreactor and algae perform the ‘water recycling’; A general diagram of Blue Marble’s manufacturing system. A photobioreactor and algae perform the ‘water recycling’; the pelletized solid waste material will be used in the gasifier. Source: Blue Marble. |

Source

Green Car Congress, 2011-06-30.

Supplier

Blue Marble Biomaterials

Blue Marble Energy

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals