In the bioeconomy, as innovations come thick and fast, it’s very easy to focus all of our coverage on these developments, ranging from new biobased products, to novel processes in the development and production of those products. However, sometimes this coverage of the products themselves can distract from what makes them so significant: the problems they solve. We are entering an era where we will face many big challenges, some of which the bioeconomy will be able to help us overcome. In this series of articles, we will look at six of these big challenges, and the solutions that the bioeconomy provides us with.

Around the world, countries are starting to publish their bioeconomy strategies, and these are just some of the issues that such policy directives will be aiming to tackle.

Problem: Plastic Waste

Problem: Plastic Waste

In recent years, as countries have begun to reduce their greenhouse gas emissions, plastic has taken over as the “poster boy” of environmental issues. Efforts are still being made to quantify the scale of the problem, but recent estimates put the amount of plastic waste produced thus far at over 6 billion metric tons. At the current rate of production, this is unsustainable, and the negative environmental effects of releasing plastic into the environment are long-documented.

Solution: Biobased Plastics (and Policy Change)

One of the most talked about innovations in the bioeconomy has been the development of compostable plastics. These buck the stereotype of plastics being “non-degradable”, as these plastics will biodegrade when subject to the right conditions. These plastics have seen use in “disposable” items, particularly ones associated with food waste. Compostable coffee pods, cups, and food waste bags have all been developed, with the intention being that they can be disposed of alongside food waste.

However, this is not without its downsides: by “compostable”, manufacturers of these plastics are usually referring to industrial composting, but this may not be clear to the consumers, resulting in the plastics not being disposed of in the correct way, thus nullifying the solution to the problem entirely.

While compostable plastics are an excellent innovation and able to act as a solution to the problem at small scales, the infrastructure isn’t there for composting on the scale needed to dispose of all the world’s potential plastic waste. This isn’t to mention that not all plastics are likely to be compostable, meaning some applications will not allow for this end-of-life treatment. This restricts the compostable plastic solution to a narrow range of sectors – mostly ones involving food – where composting is a viable method of waste disposal in the first place. So, what of the other sources of plastic waste?

For other plastic solutions, we can look to durable biobased plastics. There are now biobased drop-in alternatives for many widely used packaging plastics such as polyethylene and polyethylene terephthalate. If these plastics are subsequently recycled and fed back into packaging production, it creates a sustainable circular economy, fed by renewable feedstocks and with waste minimised. The potential is already there for this to become a viable solution, but the landscape needs to change.

As such, the real solution for successful implementation of this lies in policy change. A good example would be the recently published European Plastics Strategy, which aims to put recycling at the forefront of plastic waste management in Europe. This has been welcomed by members of the plastics industry, and by environmentalists, but to ensure it works as a strategy every aspect of the value chain needs to be geared towards recycling, right from material and product design, which will require a substantial commitment on the part of the industry itself.

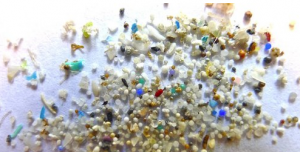

Problem: Microplastics

This is an offshoot of the previous problem of plastic waste, but is a significant enough problem in its own right to merit its own entry. Eventually, plastic waste ends up in the world’s oceans, where it is slowly broken down into microscopic particles. These have been found to be harmful to marine life, and are prevalent on a scale far greater than previously imagined. However, this is the smaller facet of the problem: recent studies have found that the majority of microplastics do not come from breakdown of waste, but come directly from product use. Such microplastics can be released into the environment purely through use of a product: one of the biggest culprits is tyres: due to abrasion of the tyre rubber, microplastics slough off and are washed into water courses by rain.

Microplastics are also intentionally included in some products: notable examples include many cosmetic products, wherein “microbeads” are used to improve texture of cosmetics, or as exfoliation agents in skincare products. The major problem here is that these products are disposed of directly into the water system when they are washed off, thus guaranteeing the presence of microplastics therein.

Solution: Degradable Microbeads

Initially, the public response to the findings about microplastics was very strong, which led to several governments announcing an outright ban on the use of microplastics in consumer products. This indeed is one viable solution, but the bioeconomy offers a more nuanced solution.

Compostable plastics were mentioned above, but these would not be suitable as microplastics, as products containing them aren’t disposed of by composting, but the bioeconomy has also managed to develop plastics that will biodegrade in more natural conditions. Several companies have developed microbeads from PHAs, biodegradable polymers produced by microorganisms, making them both degradable and biobased, demonstrating the desirable characteristics that biobased plastics can have at both ends of their life.

The important trait is the ability to degrade in marine conditions, which is actually an easier approach to the problem than trying to prevent microplastics from entering the oceans at all, simply reducing the harm they cause once there. Of course, for such a solution to be successful, it will require widespread adoption of these degradable microbeads, to prevent a shift in attitude back to acceptance of water-disposal of non-degradable microbeads, as consumers come to incorrectly believe all microbeads are safe.

Another similar possible solution was developed by the University of Bath: to make the microbeads from cellulose instead. This has broadly the same effect as the PHA microbeads, by allowing the microbeads to be degradable in marine conditions. However, these microbeads use plant biomass as their feedstock, rather than being produced by microbes. This distinction is important for wider production of these biodegradable microbeads, as this means they can be produced from different sources, and thus with different technology, meaning this solution will be easier to roll out, depending on what technology is available in what area.

In terms of the problem of microplastics produced by breakdown of larger plastics, this cannot be as easily solved, as not all plastics are degradable in marine conditions, and not all applications are suitable for plastics that are. To this end, currently the best solutions are to minimise plastic waste in its own right, to prevent this breakdown and deposition of microplastics. This all comes under the umbrella of solutions described in the first part of this article.

Plastics are without doubt one of the most successful innovations of recent memory, and simultaneously becoming one of our biggest challenges, but with the help of the bioeconomy, we may be able to solve that problem, and have plastics that work for us without issue

Author

Bob Horton

Source

NNFCC, press release, 2018-02-26.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals