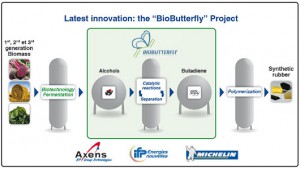

Axens, IFP Energies nouvelles (IFPEN) and Michelin have announced the launch of a plant chemistry research partnership that aims to develop and bring to market a process for producing bio-sourced butadiene, or bio-butadiene.

In response to the need to find sustainable alternative sourcing channels for elastomers, the BioButterfly process will make it possible to produce innovative, more environmentally-friendly synthetic rubber.

BioButterfly pools the strengths and skills of three key research and industry players: Axens, IFPEN and Michelin. In addition to developing an innovative bio-butadiene production process, the partners are also committed to laying the groundwork for a future bio-sourced synthetic rubber industry in France.

BioButterfly covers all research and development phases in the process – from scientific concepts, to the pilot phase and validation on an industrial demonstrator – by leveraging the three partners’ complementary skills and expertise:

IFPEN’s ability to conduct highly innovative research on industrial processes and catalyzers.

Axens’s experience in the process engineering and marketing of new technologies for transforming renewable materials.

Michelin’s expertise in developing innovative materials that make it possible to deliver more performance features in the same tire.

BioButterfly is backed by a €52 million budget extending over eight years. The project was selected by France’s Agency for the Environment and Energy Management (ADEME) to receive €14.7 million in financing as part of the Investing in the Future program.

Project challenges

Achieving superior performance will be the partners’ top priority throughout the project. Research will focus on five key challenges:

- Producing economically competitive bio-butadiene.

- Reducing environmental impacts, especially carbon emissions, across the entire production chain, compared with fossil fuels.

- Manufacturing high-performance synthetic rubber and adapting the process to all uses of bio-butadiene.

- Lowering investment costs.

- Preparing the future French bio-sourced synthetic rubber industry.

Motivation behind the partnership

“For Axens, this collaboration is an opportunity to strengthen its expertise and presence in the biomass transformation processes market in the field of biofuels and bio-based chemistry,” explains Jean-Luc Nocca, Executive Vice-President, in charge of technological development and innovation at Axens.

“IFPEN is delighted to commit to this exemplary partnership project,” says Pascal Barthélémy, Executive Vice-President of IFPEN. “BioButterfly is in line with our strategy of developing new ways of producing chemical intermediates and biofuels. In this project, we are leveraging our expertise in catalysis, separation, and process engineering to develop and extrapolate the technology.”

“This joint research project with Axens and IFPEN is an excellent opportunity for Michelin to find new sustainable sourcing channels for elastomers, which are essential for the quality of our tires,” says Terry Gettys, Director of R&D at Michelin. “The project will provide us with new high-performance, environmentally responsible materials.”

All about butadiene

Butadiene is a chemical intermediate derived from fossil resources that is used in the production of synthetic rubber. Some 60% of global output is for the tire industry. Using a renewable raw material is an attractive alternative for ensuring sustainable supply. The bio-butadiene produced will support continued innovation in procuring high performance rubber for tires.

The three partners

Axens

Axens, www.axens.net, is an international provider of advanced technologies, catalysts, adsorbents and services, with a global reputation for basic engineering design excellence. Its core businesses are the conversion of oil, coal, natural gas and biomass to clean fuels as well as the production and purification of major petrochemical intermediates. Axens’ comprehensive offer is based on highly trained human resources, modern production facilities and extensive commercial feedback from plants using its processes and catalysts around the world.

IFP Energies nouvelles

IFP Energies nouvelles (IFPEN), www.ifpen.com, is a public-sector research, innovation and training center active in the fields of energy, transport and the environment. Its mission is to provide public players and industry with efficient, economical, clean, sustainable technologies to meet the challenges facing society in the areas of climate change, energy diversification and water resource management. It is internationally recognized for its expertise.

Michelin

Michelin, www.michelin.com, the leading tire company, is dedicated to sustainably improving the mobility of goods and people by manufacturing and marketing tires for every type of vehicle, including airplanes, automobiles, bicycles/motorcycles, earthmovers, farm equipment and trucks. It also offers electronic mobility support services on ViaMichelin.com and publishes travel guides, hotel and restaurant guides, maps and road atlases. Headquartered in Clermont-Ferrand, France, Michelin is present in more than 170 countries, has 113,400 employees and operates 69 production plants in 18 different countries. The Group has a technology center in charge of research, development and process engineering, with operations in Europe, North America and Asia.

Source

IFP Energies nouvelles, press release, 2013-11-07.

Supplier

Axens Technologies (IFP)

IFP – Innovation, Énergie, Environnement

MICHELIN

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals