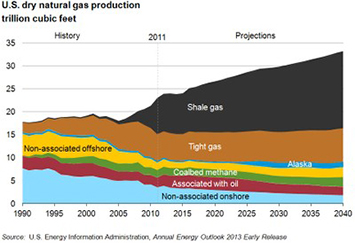

Shale gas production in the US has risen dramatically over the past five years. In 2007 annual production of shale gas in the US was 1.29 trillion cubic feet but by 2010 this had risen to 5.34 trillion cubic feet, a 312 per cent increase in just four years.

But this is just the tip of the iceberg, according to the 2012 Annual Energy Outlook the US Energy Information Administration shale gas reserves in the US could be as high as 17,021 trillion cubic feet. By 2035 nearly half of US gas production is expected to come from shale gas, up from around a quarter in 2010.

But this is just the tip of the iceberg, according to the 2012 Annual Energy Outlook the US Energy Information Administration shale gas reserves in the US could be as high as 17,021 trillion cubic feet. By 2035 nearly half of US gas production is expected to come from shale gas, up from around a quarter in 2010.

The increase in shale gas production has brought gas prices down significantly and, over the past four years, prices have fallen by nearly 50 per cent in the US. The boom in cheap shale gas has also led many US petrochemical companies to increase their capacity to convert shale gas into hydrocarbons.

Natural gas liquids distilled from shale gas can be steam cracked to produce ethylene. This ethylene is used to produce a range of C2 hydrocarbons, which are important in the manufacture of solvents, plastics and detergents. However, ethylene cracking does not produce the longer chain C3 and C4 hydrocarbons needed in many industrial applications.

To produce longer chain hydrocarbons we need other feedstocks. Crackers that use naphtha, made from crude oil rather than shale gas, produce more complex hydrocarbons, such as propylene or butadiene. However, the increased production and lower costs of shale gas compared to crude oil means we are likely to see less naphtha cracking.

As a consequence complex hydrocarbons made from crude oil may become more expensive and their supply more unpredictable. This is creating new opportunities for speciality chemical companies who are converting biomass into C3 and C4 hydrocarbons.

Dr Adrian Higson, Head of Biorefining at NNFCC, said: “Many companies are seeing new opportunities created by the shifting availability of petrochemical feedstocks, and the market for chemicals made from renewable resources is growing rapidly.”

“Biomass can be used as an alternative to naphtha in the production of C3 or C4 hydrocarbons such as isoprene and butadiene, and this can benefit markets for downstream derivatives such as acrylic acid, succinic acid and 1,4 butanediol,” he added.

The market for bio-based chemicals is currently experiencing significant growth and the production of bio-based products is expected to generate $10-15 billion of revenue for the global chemical industry by 2020, according to a report by the World Economic Forum.

Source

NNFCC, 2013-01-16.

Supplier

NNFCC

US Energy Information Administration (EIA)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals