Up to now, the number-one biopolymer in commercial use, polylactic acid or PLA, has been available mainly from one supplier and in a limited range of varieties. But there appear to be a number of new sources waiting in the wings, who are preparing a profusion of new PLA variants-copolymers, alloys, “engineering” PLA and even “do-it-yourself” PLA.

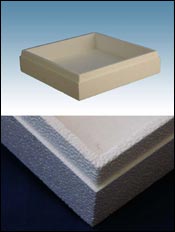

One of the most dramatic developments is that a large European molder of EPS beads has opted to polymerize its own PLA and make the world’s first expanded PLA (EPLA) bead foams. Furthermore, it will be making an improved form of PLA with superior strength and heat resistance. This is just one example of rapid development of this resin and its expansion into a family of biomaterials with a wide range of properties.

|

| World’s first expanded PLA |

Worlds first EPLA

Synbra Technology bv (the raw material development and supply unit of Synbra Group) in Etten-Leur, the Netherlands, acquired the first license for a new PLA reactor technology developed by Purac in the Netherlands and Sulzer Chemtech AG in Switzerland.

Synbra already polymerizes its own EPS beads in a batch process, but wanted to develop an expandable biopolymer packaging material. “There was no suitable material on the market,” says Jan Noordegraaf, managing director of Synbra Technology. “We couldn’t get PLA material from NatureWorks. We were told to come back in three years, so we thought, we’ll have to make it ourselves.” Since 2002, NatureWorks LLC (formerly Cargill Dow) has been the world’s only large-scale commercial producer of PLA resin.

Purac, which produces lactide monomers, the precursors of PLA, as well as medical grades of PLA, is providing Synbra with polymerization know-how, catalysts, and monomer. Sulzer has long had a static-mixer/reactor for polymerizing PS, and recently adapted it to production of PLA. Sulzer has made PLA in a lab-scale version of the new process. Before it acquired the license from Sulzer and Purac, Synbra tested their PLA material in its own EPS bead-making process, using CO2 as a blowing agent. Synbra also modified its existing EPS shape-molding equipment to handle EPLA.

Synbra is currently getting PLA from Sulzer’s lab in Switzerland and has started molding the first foam samples for customers. Sulzer will have a 50-lb/hr PLA demonstration plant running in Switzerland by the end of the year. Synbra plans to have an 11million-lb/yr semi-works PLA reactor running in the Netherlands by late 2009. Once that reactor is on line, Synbra expects to build a full scale 100-million-lb/yr PLA plant.

Synbra’s EPLA, trademarked BioFoam, will be colored light green to distinguish it from conventional white EPS. BioFoam is aimed at specialty packaging for consumer goods and at bio-derived cushion filling. In the Netherlands, the market leader in beanbag furniture, Fatboy the Original bv, has signed up to use BioFoam beads for filling.

Top-load strength of EPLA is comparable to that of conventional EPS, Synbra says, but without the problems associated with pentane blowing agents. EPLA beads contain no VOCs and have no shelf-life limitation. Synbra already plans to bring BioFoam to North America. “BioFoam will be global,” Synbra’s Noordegraaf predicts.

|

| Sulzer Chemtech’s static-mixer reactor |

Polymerizing PLA

Sulzer’s PLA process is a continuous, two-reactor series occupying a space about 40 ft square. The first reactor is an SMR (Sulzer Mixer Reactor) in a loop configuration with static mixers inside. The second reactor is a straight-through SMR reactor.

Both reactors run at relatively high temperatures, heated by the catalyst reaction. Polymerization occurs along the inside shell of the SMR cylinder. The static mixers inside the reactors are a series of bent tubes through which a cooling medium travels to remove excess heat and control the reaction rate of polymerization.

After the two reactors comes a devolatilization unit, which strips off any unpolymerized monomer. Polymer then goes directly into a pelletizer—there is no extruder. Sulzer’s PLA process is only available for use with Purac’s lactides.

Lactide is shipped as an inert flake in dry bulk containers. The only difficulty transporting and storing lactide is that it must be protected from moisture by special packaging, or it reverts to lactic acid again.

The new ‘D’ Monomer

Before now, PLA couldn’t be used for expanded bead foam because it was too brittle and too heat-sensitive for the reheating and expansion of shape molding. (PLA typically has an elongation at break of only around 4%.) Synbra’s solution is to use a stereo-complex PLA made with a new D-lactide monomer that became commercially available in August, when Purac started up the world’s first D-lactide production at a 10-million-lb/yr plant in Spain.

Lactides come in two forms, “L” or right-handed, the naturally occurring form used to make commercial PLA, and “D” or left-handed, a specialty monomer previously made only in R&D labs. In Spain, Purac produces both D-lactide to make PDLA homopolymer and L-lactide to make PLLA homopolymer.

The availability of D-lactide monomer is a game changer for PLA. It’s already appearing in exotic PLA materials that are in limited commercial use. Applications include engineering polymers for injection molding of small parts, high-heat fibers, and microwaveable thermoformed trays.

D-lactides can be polymerized into a PDLA homopolymer. This can then be alloyed with standard commercial PLA (which is mostly PLLA with small amounts of PDLA impurities) to make new stereo-complex PLA. Self-nucleating stereocomplex PLA has the highest strength, crystallinity, and heat resistance in the PLA spectrum (see figure). Its melt-temperature range is 428 to 446 F, vs. 300 to 320 F for standard PLA. HDT is 320 to 330 F for 50/50 PDLA/PLLA vs. 212 to 300 F for highly crystalline PLLA and 130 to 140 F for standard PLA, Purac says.

Emerging High-end PLA

Purac ships D-lactide to over a half-dozen development partners besides Synbra, most of them in Asia. Except for Synbra, these are all companies that already have pilot or semi-works PLA plants and are developing new versions of the bioresin.

For example, Mazda in Japan uses high-heat PLA fiber from Teijin Fibers for automotive upholstery and high-heat rigid PLA molded parts for an instrument panel and glove-box lid. Both were introduced on the limited-release 2007 Premacy Hydrogen RE hybrid car, available only in Japan. The PLA fiber is a stereo-complex PLA with HDT of 320 F. The rigid PLA was developed by a consortium of Japanese government, industry, and academic researchers. It is a stereo-block copolymer of D and L lactides and includes a copolymer of starch and PDLA as a nucleating agent. It reportedly has high crystallinity and an HDT above 212 F. An impact-modified PLLA is used as an additive to reduce brittleness.

Samsung Cheil Industries, a Korean plastics and textiles maker, is also studying stereocomplex PLA in R&D as a way to enhance properties. Samsung Cheil announced its PLA alloy technology at the recent SAE Automotive Composites conference in Troy, Michigan. Samsung described alloys of PLA with ABS or PC, plus nucleating agents and glass fiber. These PLA alloys are being injection molded into housings for three cell-phone models, which were commercially introduced last June in Europe and in Asia.

Samsung Cheil reports that PLA with 30% glass fiber and a special nucleating agent achieves an HDT of 302 F. Samsung is also developing long-glass PLA composites to increase heat and impact resistance.

Also working on PLA alloys is Toray Industries, Inc. of Japan. It is developing Ecodear “nano-alloys” of engineering thermoplastics like polycarbonate dispersed in nano-scale domains within a PLA matrix. Initial projects involved a laptop computer housing, cell-phone charger, and cell-phone housing. Just last month, Toray and Canon Inc. of Japan announced that they are jointly developing exterior parts for Canon office equipment using Ecodear materials that consist of more than 25% PLA and other unidentified ingredients. Canon says these materials have achieved a flame-retardant rating of UL 94-5V, reportedly the highest FR rating yet for a bioplastic.

Unitika Ltd. in Japan has been developing PLA compounds for 10 years, originally improving heat stability with natural fibers, such as a cell-phone housing for NEC in 2006 made of PLA reinforced with kenaf plant fiber. Last year Unitika reported the development of a new grade of its Terramac PLA with rapid crystallization and higher heat resistance. It reportedly can be injection molded with 30-sec cycle times, about 40% faster than standard PLA.

More PLA Processes

A Swiss investment group recently announced its intention to produce PLA in Europe. Pyramid Technologies Ltd. plans to set up an operating company, Pyramid Bioplastics, to use a PLA polymerization process licensed from Uhde Inventa-Fischer GmbH (a unit of Thyssen Krupp) in Berlin, Germany. Pyramid plans to build an 11-million-lb/yr semi-works PLA plant in Guben, Germany, by 2012. The group ultimately wants to build a 130-million-lb/yr plant.

Uhde’s twin-reactor process is based on its continuous stirred reactor technology for nylon 6 and PET. Uhde has a 4-lb/hr pilot plant for PLA, and Uhde Biotechnology in Leipzig, Germany, has a pilot plant for making lactic acid, which is fermented from plant starch or sugar. Pyramid has said that its PLA will come from beet sugar.

Meanwhile, Zhejiang Hisun Chemical Co. in Zhejiang, China, recently started up an 11-million-lb/yr semi-works PLA plant, using a process developed with the Chinese Academy of Sciences.

Source

Plastics Technology, 2008-11.

Supplier

Canon Inc.

Mazda Motor Corporation

NatureWorks LLC

PURAC S.A.

Pyramid bioplastics Guben GmbH

Pyramid Technologies

Samsung Electronics

Sulzer Chemtech Ltd.

Synbra

Teijin Ltd.

Toray Industries Inc.

Uhde Inventa-Fischer

UNITIKA Ltd.

Zhejiang Hisun Chemical Co.

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals