- Biological methanation as a new process technology

- End of 2016: Sales launch of the Audi A4 Avant g-tron

Audi is expanding capacities for the production of its sustainably produced e-gas. Effective immediately, the Viessmann Group is the first partner company to produce additional quantities of the synthetic fuel in a new type of biological process. The pilot plant in Allendorf in the German state of Hesse was officially opened on Monday.

Audi e-gas is generally produced in two key process steps – electrolysis and methanation. In the first step, renewably generated electricity is used to split water into hydrogen and oxygen. In the second step, the hydrogen is reacted with CO2 to yield synthetic methane. In the Audi e-gas plant in Werlte in the German state of Lower Saxony, this is done using a chemical-catalytic process under high pressure and high temperature.

In the new Viessmann plant, methanation is now purely biological. Highly specialized microorganisms absorb the hydrogen that is dissolved in liquid and the carbon dioxide through their cell walls. From these molecules they then form the new molecule methane. The process is run under a moderate pressure of around five bar and at relatively low temperatures. “We are writing the next chapter of the Audi e-gas story here,” said Reiner Mangold, Head of Sustainable Product Development at AUDI AG, during the opening celebration. “Audi began to produce the sustainable fuel in Werlte around two years ago. Now we are also working with a partner who immediately contributed this new process.”

The pilot plant sets another technical milestone: It is the first power-to-gas plant to utilize biological methanation across Germany. Its strength lies in the fact that it processes the carbon dioxide contained in the raw biogas directly. Unlike chemical methanation, the CO2 does not need to be present in high concentration or purified form. This opens up new procurement paths. Smaller sewage treatment and biogas plants, in which no biogas purification is performed, can now come into consideration as CO2 sources.

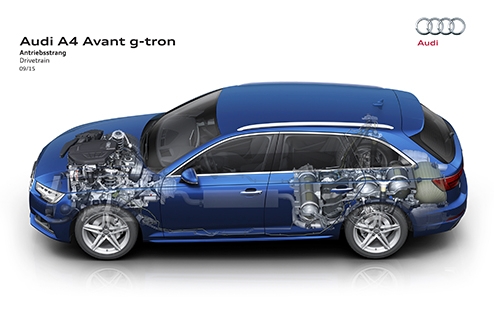

Thanks to the new partnership, Audi will be able to supply a growing number of customers with sustainably produced e-gas in the future. Simultaneously, the brand with the four rings is also extending its line-up of models with natural gas drive. At the end of 2016, sales of the new Audi A4 Avant g-tron begin in Europe. This is the second CNG model from Audi after the Audi A3 Sportback g-tron, which has been on the market since the beginning of 2014. Customers can run both g-tron models on gasoline as well as on conventional natural gas, biomethane or the sustainably produced Audi e-gas.

The Viessmann Group started up its pilot plant in stages beginning in March 2015. Like the Audi e-gas plant in Werlte, it consumes tons of CO2 in the production of the synthetic gas. Participating at the official opening of the plant in Allendorf along with Reiner Mangold, Head of Sustainable Product Development at Audi, were the Minister-President of Hesse, Volker Bouffier, and Prof. Martin Viessmann, CEO and partner of the Viessmann Group.

Fuel consumption of the models named above:

Audi A4 g-tron:

This car is not yet on sale. It has not yet been homologated and is therefore not subject to the 1999/94/EG guideline.

Audi A3 Sportback g-tron:

CNG consumption in kg/100 kilometers: 3.6 – 3.3 (7.9 – 7.3 lb); Combined fuel consumption in l/100 km: 5.5 – 5.1 (42.8 – 46.1 US mpg); Combined CO2 emissions in g/km (CNG): 98 – 89 (157.7 – 143.2 g/mi); Combined CO2 emissions in g/km (gasoline): 128 – 117 (206.0 – 188.3 g/mi)

Fuel consumption, CO2 emission figures and efficiency classes given in ranges depend on the tires/wheels used.

Source

Volkswagen AG, press release, 2016-02-29.

Supplier

Audi AG

VIESSMANN Werke GmbH & Co. KG

Volkswagen AG

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals