- Bio-on has patented a new material following research conducted over the last 2 years by CNS laboratories in Italy and Clarkson University in New York state.

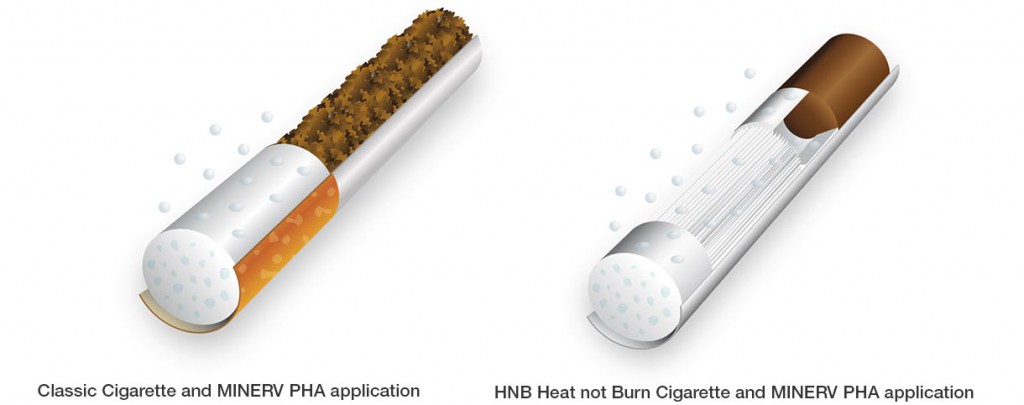

- The new product, a natural and biodegradable polymeric liquid made from the revolutionary bioplastic Minerv PHA developed by Bio-on, can replace the triacetin used in cigarette filters and block up to 60% of harmful substances (ROS or Reactive Oxygen Species) for the human body.

- Production has already begun at Bio-on’s plant and will be extended to licensees’ plants.

Bio-on, listed on the AIM segment of Borsa Italiana and operating in the high quality bioplastic sector, announces extraordinary results achieved by its researchers: a 100% natural and biodegradable polymeric liquid has been created using a special process that can replace the triacetin used in old and new generation cigarette filters. Two results have been achieved: replace the adhesives currently used by the tobacco industry in cigarette filters and introduce a natural filter that blocks up to 60% of the Reactive Oxygen Species (ROS) harmful to the human body, without changing the nicotine taste.

“This innovation is destined to revolutionise the tobacco sector,” says Bio-on Chairman and CEO Marco Astorri, “and we are very proud of the teamwork that has been done over the last 24 months by our researchers in Italy in our CNS Business Unit (Cosmetic, Nanomedicine & Smart Materials), and by the scientists at Clarkson University.”

One cigarette currently contains approximately 50 mg of triacetin, which is not naturally biodegradable and therefore further slows down the disintegration of the cellulose acetates. Over 5.5 trillion conventional cigarettes and 40 billion new-generation, heat-not-burn cigarettes are produced and sold every year.

Bio-on is in contact with the largest global tobacco manufacturers. Production of the new polymeric liquid has already begun at Bio-on’s plant in Castel San Pietro Terme near Bologna, Italy and will be rapidly expanded to the licensees that have already entered agreements with Bio-on. The company is already ready to produce 15,000 tons per year (2019-20) and, in the light of the great interest it is receiving, expects to triple that amount from 2021.

“Exposure to ROS through cigarette smoking is a serious threat to the smoker’s health,” explains Mauro Comes Franchini, Scientific Director Business Unit CNS. “Our researchers, in collaboration with Clarkson University, have found an effective solution to block these species in the filter. The solution is natural and environmentally friendly, as these innovative filters exploit the chemical and structural characteristics of polyhydroxyalkanoates (PHA – the biopolymers developed by Bio-on).” This innovation “is already industrialised and ready to scale up to the global market,” adds Paolo Saettone, Managing Director Business Unit CNS.

“Our company is entering the enormous tobacco market as a leading player, “says Bio-on Chairman and CEO Marco Astorri. “Users stand to benefit greatly from this innovation, which is all down to our 100% natural Minerv PHA biopolymer. We have filed the first patents on a broad range of innovations in tobacco and we are especially pleased that it all comes from Italian ideas and technologies.”

All the biomaterials developed by Bio-on (PHAs or polyhydroxyalkanoates and PHBs or polyhydroxybutyrate) are made from renewable plant sources with no competition with food supply chains. They can guarantee the same thermo-mechanical properties as conventional plastics with the advantage of being completely eco-sustainable and 100% naturally biodegradable.

About Bio-on S.p.A

Bio-on S.p.A. is an Italian Intellectual Property Company (IPC) operating on an international scale. Listed on the AIM segment of Borsa Italiana since 2014, Bio-on licenses and manufacturers the world’s most innovative bioplastics, conducting applied research and developing advanced bio-fermentation technologies, and cutting-edge natural and sustainable chemicals for the future. Bio-on’s biopolymers, PHAs or polyhydroxyalkanoates, are made from renewable plant sources with no competition with food supply chains, including molasses and sugar beet and sugar cane syrups, fruit and potato waste, carbohydrates, glycerol, waste frying oil and even carbon dioxide in the atmosphere.

Bio-on bioplastics, called Minerv PHAs, have the same thermo-mechanical properties as conventional oil-based plastics with the advantage of being completely eco-sustainable: 100% natural and 100% biodegradable, as certified by Vincotte and by USDA (United States Department of Agriculture). The great versatility of PHAs means Bio-on can produce Minerv PHAs bioplastic in microscopic dimensions to replace the invisible microbeads used in cosmetics products, in professional SLS 3D printers, fragrances, animal feed and many other applications.

To promptly meet the exponentially rising and increasingly diversified demand, Bio-on, which is already working alongside big multinationals to develop alternatives to conventional plastics, operates through six Business Units: Bio-on Plants, RAF, Recovery And Fermentation, CNS (Cosmetic, Nanomedicine & Smart Materials), SMD (Structural Materials Developments), fdm (Fashion Development Material) and ENG (Engineering).

Source

Bio-on, press release, 2019-06-03.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals