Professor Gadi Rothenberg of the Research Priority Area Sustainable Chemistry was awarded a first-phase valorisation grant by the Dutch Technology Foundation (STW) to try and bring to market the innovation of Plantics – alternative plastics made from plants.

The project is a collaboration between the University of Amsterdam (UvA) and Plantics BV, a new bio-plastics spin-off company led by Helias Andriessen and Albert Alberts. The STW Take-off programme aims to aid scientific start-ups in bringing their innovations to the market.

Accidental discovery

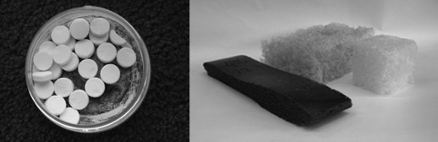

Plantics was founded after Alberts and Rothenberg discovered by accident a new type of biodegradable polymer in 2011 while researching catalytic biomass conversion. This new non-toxic, non-hazardous plastic is made from 100% plant-based materials, and cheap enough to replace polyurethane and in some cases polypropylene and PET. In a successful collaboration with the Amsterdam University of Applied Sciences (HvA), product designers used the new plastics for making various innovative products. With help and active support from the Van‘t Hoff Institute for Molecular Sciences and the UvA’s Technology Transfer Office, the new materials were developed and patented. The spin-off company Plantics BV was then set up to bring these new materials to the market.

Economical viability studies

The €40,000 grant will be used for market studies, material certification and risk analysis, with the aim of building a valid business case for manufacturing and marketing the new plastics. According to Rothenberg, there are opportunities for biobased companies in Amsterdam: ‘Amsterdam is a forward-thinking city, where sustainability is highly valued. There are several companies making and using biobased materials, with encouragement and support from the city and the region. But ‘green’ alone is insufficient – there has to be true economic benefit for companies to succeed. With the studies of this Take-off project, we hope to prove that making plastics from plants is not only sustainable, but also economically viable.’

Source

University of Amsterdam, press release, 2015-02-04.

Supplier

Amsterdam University of Applied Sciences

Plantics BV (Materia)

STW

University of Amsterdam IVAM

Van‘t Hoff Institute for Molecular Sciences

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals