In 2017, the BECK Fastener Group (Austria) and DR. HANS KORTE Innovationsberatung Holz & Fasern (Germany) introduced the world’s first collated wooden nail to the market. The nails are made from indigenous beech wood and bring a pull-out strength that is higher than steel nails. Whether the wooden nails also are a more sustainable option has been investigated by the nova-Institute via life cycle assessment. The results are promising!

The LignoLoc® wooden nail is manufactured from sustainably sourced, PEFC-certified beech wood and it is hardened by compressing the cell structure and permeating it with phenolic resin. With a pneumatic nailer the nail can be shot into wood with high speed, where friction heat on the surface causes welding between nail and the surrounding wood, providing the nail with a high durability.

To better understand the environmental performance of the nail, a life cycle assessment (LCA) was conducted. Following the established ISO 14040/44 guidelines, the LCA identified hotspots during the production of the wooden nail: The highest environmental impacts are caused by the compaction of the beech wood with the phenolic resin, where the production of the phenolic resin itself and the long press times plus heat requirements to compact the wood are the two main contributing factors.

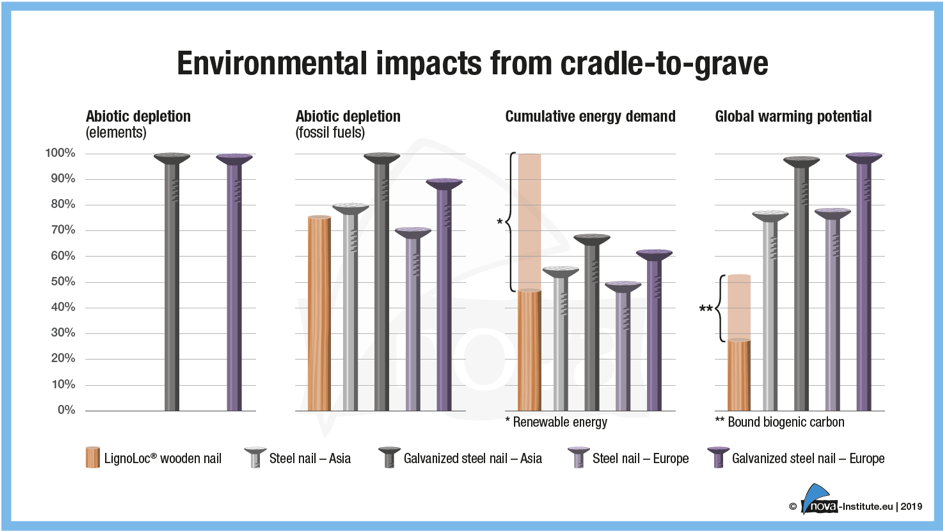

Furthermore, the study compared the wooden nail to functionally similar steels nails from cradle-to-grave, leaving out the use phase. The results are promising: under the stated assumptions, the LignoLoc® wooden shows lower global warming potential with additional benefits for binding CO2 during its lifetime. It has a lower abiotic depletion of elements, in particular when the steel nail is galvanized with Zinc. The abiotic depletion of fossil fuels is on a similar level. The cumulative energy demand is higher, but this is in a large part caused by the inherent sunlight energy stored in the beech wood.

Figure 1: Environmental impacts of the LignoLoc® wooden nail in comparison to functionally similar steel nail variants from cradle-to-grave excluding use phase

As nails can be used in a multitude of applications, it was considered not feasible to identify a standard use for the LCA. To at least provide a glimpse of the potential impact of the use phase, one use case scenario was considered for nails used in the European EPAL pallet system. Here, the lower weight of the wooden nail can provide additional advantages: Replacing steel nails with functionally similar LignoLoc® wooden nails would reduce the weight of a standard EPAL1 pallet by approximately 425 g. In a European system of 500 million pallets, the greenhouse gas emissions savings due to reduced transport loads can add up to significant amounts.

The summary of the full LCA report can be downloaded at http://bio-based.eu/ecology/#LignoLoc

Author

Christopher vom Berg, Michael Carus

Source

nova-Institut GmbH, 2019-06-04.

Supplier

BECK Fastener Group

nova-Institut GmbH

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals