Natural fibers have many advantages: they are renewable, biodegradable and robust. They are more energy-efficient to produce than glass or carbon fibers, are lighter and have better acoustics. Their disadvantage: they absorb water very easily. This impairs their mechanical properties. Fraunhofer researchers have collaborated with their partners to combine a special fiber treatment and a yarn technology: as a result, natural fibers can fully exploit their advantages and be used more widely.

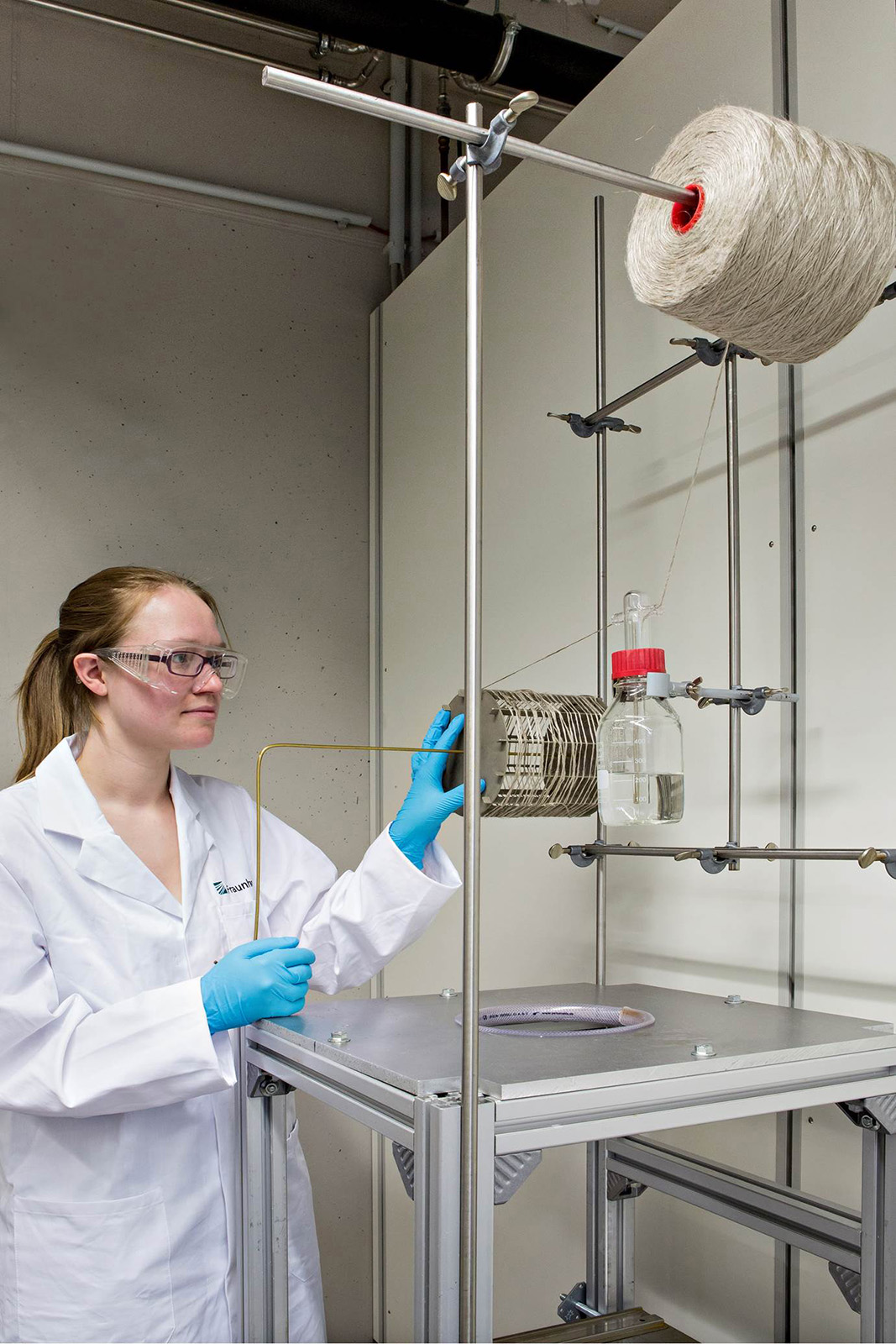

To make the natural fibers more resistant, the roving is impregnated with monomers: the polymerization then proceeds within the yarn.

The topic of biological transformation is on everyone’s lips. This type of management focuses on the sustainable use of biological resources such as plants or microorganisms. In the future, it is expected to reduce reliance on fossil fuels such as oil, coal or gas and help tackle major challenges such as climate change and global population growth. The biological transformation offers options and opportunities for almost all industries. One field of application for biological resources is materials – such as natural fiber reinforced plastics (NFRP). Their advantages make them interesting as an alternative to glass and carbon fiber reinforced plastics (GRP or CFRP): they are renewable, biodegradable and robust, use less energy in being produced, are lighter and have better acoustic properties. The disadvantage so far: they absorb water very easily, are damaged as a result and lose their otherwise positive mechanical properties.

Fiber treatment and yarn technology cleverly combined

The Fraunhofer Institute for Structural Durability and System Reliability LBF in Darmstadt, Germany has now solved this problem together with the Institute for Textile Technology (ITA) of the RWTH Aachen in the exploratory study “Bastfix”, which is funded by the German Federal Ministry of Education and Research (BMBF). The approach: A clever combination of special fiber treatment and yarn processing. “A surface treatment of natural fibers with water-repellent layers alone doesn’t provide any progress”, explains Dr. Roland Klein, group manager for design of interfaces in the plastics division at the LBF. “The water then continues to penetrate the natural fiber via cut edges or other damage.” For this reason, the scientists have treated the fibers so that they are moisture-repellent on the inside. They did this by producing polymers inside the natural fibers. “First, we let the monomers of the plastic penetrate into the cavities of the natural fibers. The polymerization then took place directly inside the fibers,” Klein says in describing the core of the new fiber treatment. The use of the method is particularly interesting for thermoplastic fiber composites, since in their production, the molten polymer is very viscous, does not penetrate into the interior and only wets the fibers superficially. The advantage of thermoplastics: they can be deformed as desired even after production.

New fields of application for NFRP

In their experiments, the researchers used flax fibers in the form of a roving, i.e. the state before spinning into yarns and their further processing into textile surfaces. This has the advantage that the fibers can be completely soaked with the monomer, since they are still present individually. Complete impregnation might not be guaranteed on fabric or twisted yarn. This is where the yarn process of the ITA comes into play. In the wrap spinning process, the Aachen scientists arrange the natural fibers in parallel and wrap the parallel core of the flax fibers with a filament. The advantage: The fibers are not twisted, which gives them increased strength. “By combining both processes, the physical properties of natural fibers can be fully exploited. These two developments greatly expand the area of application for NFRP, with the result that they can also be used outdoors and in highly stressed components,” says Klein in describing the added value. So far, NFRPs are used mainly in cars, such as for the interior lining of doors.

For his research, Klein and his team received the “DNFI Innovation in Natural Fibers Award 2017”. Fifteen textile organizations had founded the Discover Natural Fibers Initiative (DNFI) after the 2009 United Nations International Year of Natural Fiber.

Bastfix

The abbreviation “Bastfix” stands for the specific research topic “Reduction of the moisture absorption of bast fibers and the production of low-twist staple fiber yarns for use in structural components”. The German Federal Ministry of Education and Research (BMBF) funded the project as part of the ideas competition “New Products for the Bioeconomy”. The task of the Fraunhofer Institute for Structural Durability and System Reliability LBF in Darmstadt was to develop a suitable technology and to acquire its first project partners, and all within nine months. The project has now been completed successfully. Now, the project partners are looking for companies that want to bring the new process to market maturity. Further details.

Source

Fraunhofer-Gesellschaft, press release, 2018-02-01.

Supplier

Bundesministerium für Bildung und Forschung (BMBF)

Fraunhofer-Gesellschaft

Fraunhofer-Institut für Betriebsfestigkeit und Systemzuverlässigkeit (LBF)

Institut für Textiltechnik (ITA) – RWTH Aachen

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals