The 3BCAR Carnot Institute is supporting work on the concept of dry biorefining applied to lignocellulosic biomass. Two concepts are under study: the development of a fuel in powder form and the use of electrostatic separation applied to the fractionation/enrichment of biomass.

Dry biorefining is a concept that corresponds to a series of mechanical processes (grinding, fractionation, separation, etc.) that enables the production of biomass powders with targeted properties for applications in different sectors. These processes are integral to sustainable biorefining because they are solvent-free and do not require the use of inputs. The aspect that requires optimisation is the energy consumption necessary for grinding processes in order to ensure good environmental performance.

The 3BCAR Carnot Institute is supporting these dry biorefining technologies by funding different studies.

Biomass powders as fuel for combustion engines

A first in-house scientific project funded by 3BCAR in two INRA and CIRAD research units in Montpellier (IATE and BioWooEB) enabled work on the concept of dry biorefining in terms of developing solid biofuels. For this, the scientists employed successive grinding processes for different types of lignocellulosic biomass (forest or agricultural products or by-products, energy crops, etc.) to produce ultrafine powders. The intrinsically explosive properties of these powders enabled their direct use as a dry fuel in conventional engines. The advantage of these solid biofuels is the direct conversion of biomass into energy.

This project enabled the filing of a patent that has been licensed to a subsidiary of a company working in the renewable energies sector so that it can develop and exploit this technology.

Electrostatic separation applied to the dry cracking of lignocellulosic biomass

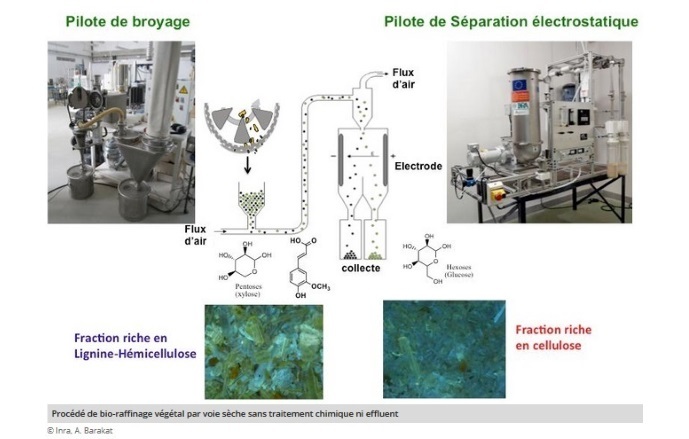

The ultrafine powders obtained during the project above were subjected to an electrostatic separation process. This process is already widely employed (sorting of electrical and electronic waste, mineral powders, the sorting for recycling of plastic materials, etc.) and consists in applying an electrical charge to the surface of particles (triboelectric effect) and then separating them under the effect of an electrical field to an anode or cathode so that they can be recovered after a final cyclone separation stage. When repeated several times, this separation can obtain different sub-fractions enriched in cellulose or lignin. This innovation has been protected by a second patent, which is also under license. The studies were carried at by UMR IATE which operates a platform for grinding and fractionation by electrostatic separation, supported by the 3BCAR Carnot Institute.

More recently, the two treatments (ultrafine grinding and electrostatic separation) were tested on oilseed meals. The results proved that it is possible to recover fractions enriched in lignocellulose or proteins using an entirely dry process. A third patent has been filed. The protein-enriched fractions provide new opportunities for the exploitation of oilseed meals. For livestock feeds, they could be incorporated in rations without supplying anti-nutritional factors. In plant chemistry, it is the process itself that is likely to offer an alternative to the manufacture of protein concentrates using liquid phase precipitation.

Towards clarification and optimisation of the process

Three members of 3BCAR (the IATE Joint Research Unit in Montpellier, the LCA Unit in Toulouse and the CATAR technological resources centre) have recently initiated a new project (SurfDry). This is studying the physicochemical and surface properties involved in the fractionation by electrostatic separation of real oilseed meals and model mixtures. Understanding the phenomena and mechanisms involved will thus enable optimisation of the process in order to attain the yields and degree of purity required by industry. The project also aims to demonstrate possible enrichment with other compounds of interest, other than proteins.

If you are interested by this work, do not hesitate to contact Coraline Caullet, business manager at 3BCAR.

Contact

Coraline Caullet

Business manager 3BCAR:

Phone: +331 42 75 93 82

The patents resulting from this research

- FR1250511: Carburant solide sous la forme d’une poudre comprenant un constituant lignocellulosique (solid fuel in powder form containing a lignocellulosic component)

- FR1363543: Procédé de fractionnement voie sèche de biomasse lignocellulosique (dry fractionation process for lignocellulosic biomass)

- FR1363534: Procédé de fractionnement d’un tourteau oléagineux et applications de ce procédé (fractionation process for oilseed meals and applications of this process).

About the 3BCAR Carnot Institute

Accreditation as a Carnot Institute is awarded to public research structures to certify their scientific excellence and professionalism in their partnership relations

3BCAR offers integrated and multidisciplinary r&D mobilising biotechnologies and green chemistry, components of the bioeconomy, to enable industrial innovations in the fields of bioenergies and biosourced molecules and materials.

To maintain its scientific advances, 3BCAR funds innovative internal projects in the form of annual calls for projects that are selected using criteria of excellence and transferability. The Institute also has ISO 9001 certification regarding the implementation of good contractual and intellectual property practices with its industrial partners.

3BCAR is a network comprising 18 R&D entities ranging from laboratories to pilot plants. It assembles skills that extend from biomass production and biorefining to functional properties.

Author

Alexandre Brosse

Source

INRA, press release, 2019-02-02.

Supplier

3BCAR Carnot Institute

Center for Agricultural Research for Development (CIRAD)

French National Institute for Agricultural Research (INRA)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals