Lignin an ugly, unwieldy molecule! The term coined by most early pioneers within the renewables industry to describe Lignin. As large, and complex the molecule seems to be, that’s not its only possible form, either, and depends on where your sample of biomass originated. Lignin comes in all sorts of shapes and configurations, and they are all frustratingly good at protecting the plants producing them. Lignin is a natural adhesive that gives trees (as well as grasses and straw) their strength and flexibility. On average, trees are 15 – 30% lignin by weight and 40% by energy.

For producers of biofuels, though, it’s a very bad thing. The general verdict across the board was to go after the low hanging fruit i.e. cellulose and hemicellulose but when it came to lignin the general consensus was, ‘You can do anything with it, except make money.’ In various current bio-refinery concepts, the cellulose and hemicellulose fractions are used to produce liquid transport fuel or products, while lignin is most often relegated to low-value uses including combustion.

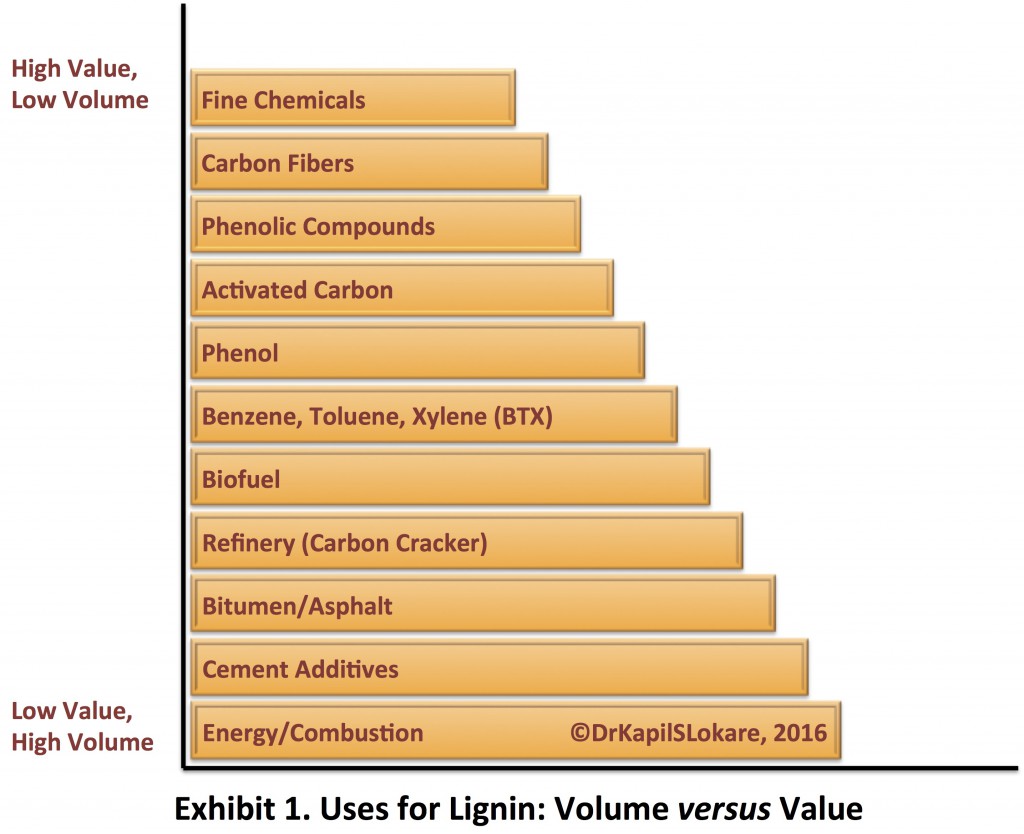

In currently operating bio-refineries, 98% lignin is either burned to produce process heat and recover pulping chemicals in paper mills, or sold as a natural component of animal feeds in wet or dry corn mills. Until very recently, this is how the industry perceived lignin. But times are changing. Lignin has developed from a residue that was only useful as a fuel for producing cellulose into a sustainable and very satisfactory alternative to fossil fuels. You can even use it to make vanilla. See Exhibit 1 for the various uses for lignin.

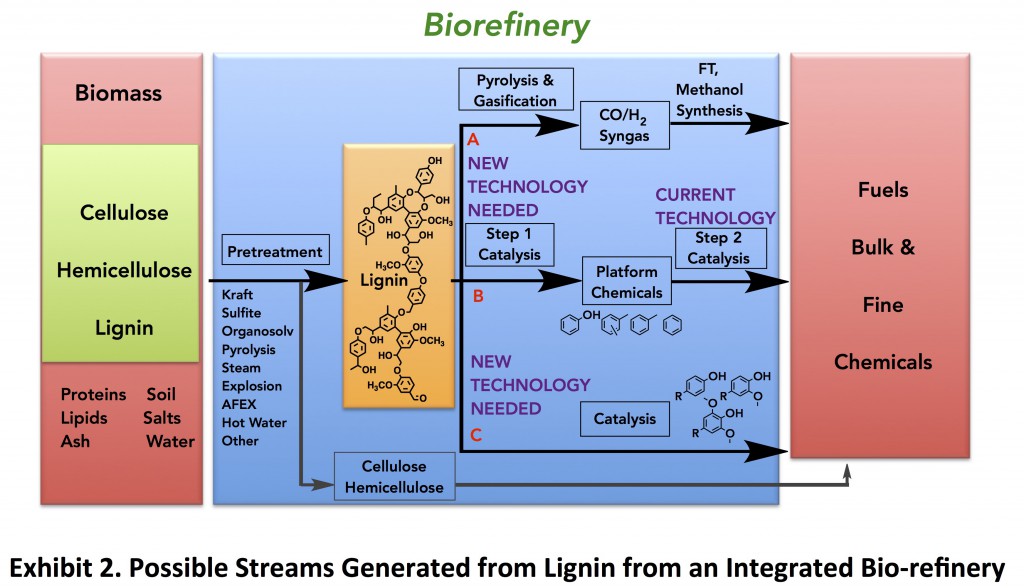

Lignin is the second most abundant natural polymer in the world, yet its direct utilization or de-construction to valuable components makes up only a tiny fraction of the billions of pounds processed from harvested wood and other lignocellulosic crops. There is no doubt that our society is placing a renewed emphasis on the possibility of using lignin streams as a replacement for aromatic components of petrochemical origin. See Exhibit 2 for the possible streams that may be generated from lignin from an integrated bio-refinery that currently utilizes only the cellulose and hemicellulose components.

A cursory examination of the literature over the past 10 years shows tremendous activity in this area, with many patents/publications appearing, addressing various aspects of lignin chemistry and utilization. Despite this interest, however, obstacles remain toward making this valuable resource a feedstock and reality for many of our industry’s processes.

Lignin is also released when cellulose-ethanol is made from biomass, and it is commonly used as an adhesive in cement. Lignin also happens to be a perfect alternative for synthetic adhesives, in fibreboard for example. Synthetic adhesives are made from crude oil. And certain components, such as formaldehyde, are highly toxic. This substance is on the list of extremely carcinogenic substances in the US. We want to stop using it, but first we need a viable alternative. And lignin fits the bill perfectly.

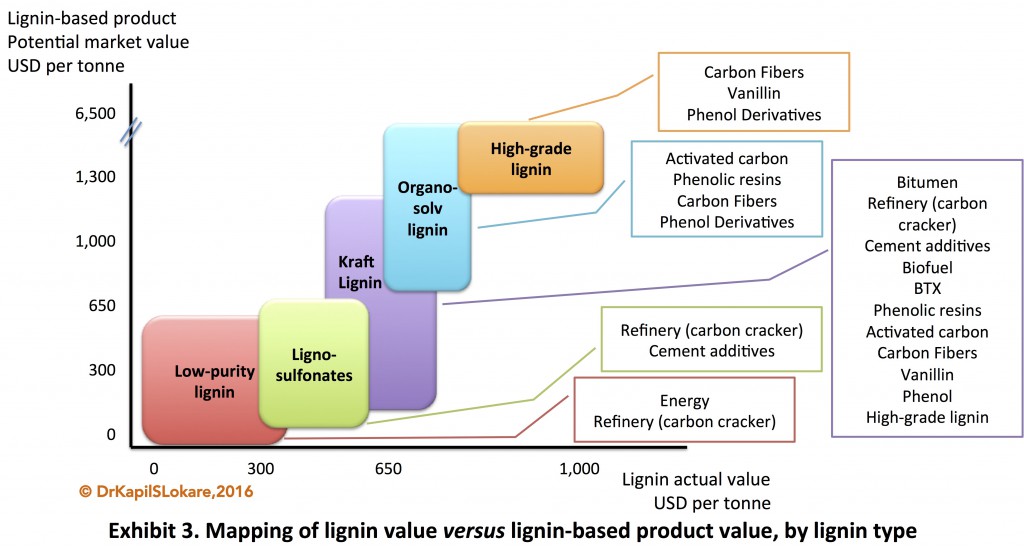

Lignin streams impose significant technical challenges to becoming and/or replacing most petrochemical-based feedstock’s due to its inherent variability, and heterogeneity. Numerous process variations including seasonal feedstock variability, related delignification alterations, which are all currently based in producing cellulosic materials, create an inherently complex mixture of unpredictable specifications. See Exhibit 3 for the various valuated forms of lignin, by lignin type currently produced.

Applications needed

This reality necessitates that any lignin streams that are envisaged to become feedstock’s for further utilization need to first be refined to a set of products to meet consistent specifications. To draw a parallel to crude oil utilization, where refining operations take an otherwise intractable mixture, that is only good as a fuel, and refine it to a multitude of chemicals, which are then the foundation of the chemical industry. In this respect, lignin refining or fractionation efforts are pivotal and need to become part of our thinking prior to any of the proposed lignin utilization avenues can be industrially viable.

The lignin community needs to become acutely aware of the need to offer the user sector a product of consistent specifications on a daily basis. Technically sound and economically feasible advances in lignin refining are thus essential. The economic challenges that lignin products face are related to competition from petrochemical sources. As long as the price of oil remains low these constraints can only become more acute. In addition, the current low price of lignin offers relatively low financial margins for producing lignin feedstock’s with consistent specifications. Consequently, the industry needs to apply a large degree of innovation so as to create useful value-added products based on lignin.

Big for pulp & paper

It is without a doubt that the pulp and paper industry and possibly emerging bio refineries will be the prime candidates to offer lignin streams to society for further utilization. In both cases, however, the current objective of these industries is not to make lignin for further utilization but to make paper, bioethanol, or other products. In this respect, lignin has always been a secondary product and treated as such. This situation presents challenges in convincing the user sector to include lignin in their feedstock.

Although all of the above considerations may offer a picture of a rather intractable problem, the potential of lignin as a feedstock is enormous due to its aromatic, phenolic, reactive character and its abundance. Significant advances are apparent and demonstrate that, indeed, technical lignins can be economically and reproducibly fractionated to discrete and uniform “cuts”.

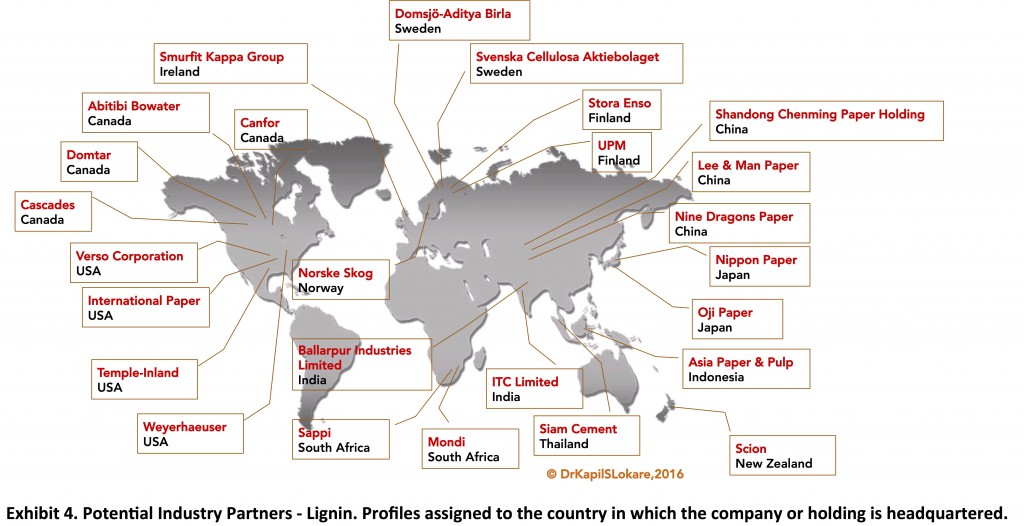

To conclude, the issue of lignin utilization rests in the hands of researchers, lignin producers, and users. Researchers need to become acutely aware of the difference between Innovation and Invention. In other words, researchers need to gain the confidence and work closely with lignin producers and the user sector to ensure the transition from idea to application becomes seamless, a strong tie with the paper and paperboard companies might be useful, Exhibit 4. Lignin producers and innovators need to be able to converse and convincingly connect with the chemical and allied industries, demonstrating that they can provide a reliable feedstock. This can only occur if the lignin producers and innovators show a serious commitment to such an endeavour that will require a major cultural shift by no longer treating lignin as a secondary by-product but treat it with the respect accorded to a valuable chemical feedstock.

Source

Lee Enterprises Consulting, 2016-12-04.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals