Electricity harvested from the sun or wind can be used interchangeably with power from coal or petroleum sources. Or sustainably produced electricity can be turned into something physical and useful. Researchers in Arts & Sciences at Washington University in St. Louis have figured out how to feed electricity to microbes to grow truly green, biodegradable plastic, as reported in the Journal of Industrial Microbiology and Biotechnology.

“As our planet grapples with rampant, petroleum-based plastic use and plastic waste, finding sustainable ways to make bioplastics is becoming more and more important. We have to find new solutions,” said Arpita Bose, assistant professor of biology in Arts & Sciences.

Solar expansion continues at Washington University

Renewable energy currently accounts for about 11% of total U.S. energy consumption and about 17% of electricity generation.

One of the main issues with renewable electricity is energy storage: how to collect power generated during the sunny and windy hours, and hold it for when it is dark and still. Bioplastics are a good use for that “extra” power from intermittent sources, Bose suggests — as an alternative to battery storage, and instead of using that energy to make a different type of fuel.

How electricity-eating microbes use electrons to fix carbon dioxide

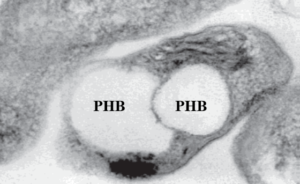

Her laboratory is among the first to use microbial electrosynthesis to wrangle a polymer called polyhydroxybutyrate (PHB) from electricity-eating microbes. The plastic they are making is “sustainable, carbon-neutral and low-cost,” Bose said.

“One of the major challenges in bioplastic production is the substrate input, which affects cost,” said Tahina Ranaivoarisoa, a research technician in the Bose laboratory and first author of the new paper. “A versatile bacterium such as R. palustris TIE-1 — which can effectively use just carbon dioxide, light and electrons from electricity or iron for bioplastic production — broadens the substrates that could be used in bioplastic production.”

In a related paper in the journal Bioelectrochemistry, Bose’s research team illustrated how TIE-1 interacts with various forms of iron while also using electricity as a source of electrons. The researchers were able to improve production rates for PHB by manually coating electrodes that the microbes used with a special kind of rust, which increased their electricity uptake.

Bose believes that microbially derived bioplastics have a future role to play in space, where astronauts could use 3-D printer technology to manufacture their own tools instead of transporting everything ready-made from Earth.

“Our observations open new doors for sustainable bioplastic production not only in resource-limited environments on Earth, but also during space exploration and for in situ resource utilization on other planets,” Bose said.

Funding provided by Department of Energy (DESC0014613); Department of Defense, Army Research Office (W911NF-18-1-0037); and the David and Lucile Packard Foundation (201563111).

Author

Talia Ogliore

Source

Washington University (St. Louis), press release, 2019-04-09.

Supplier

Army Research Office

US Department of Defense (DoD)

Washington University (in St. Louis)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals