Over the previous 9 months Zelfo Technology has been participating in BioTHOP a agro-residual up-cycling project. The project consists of a five EU country team and is supported via the EU Life initiative. The teams objectives are centred around the the post harvest ecological and commercial optimisation of hop stems and their stalk suspension systems. There are 3 main objectives: 1. to validate the performance characteristics of PLA suspension wires, 2. to prove that composting of such combined hops and string waste is viable as an ecological system, 3. to use a proportion of the hops and stringing systems as a basis for materials used to form relevant new products.

The home base of the project is in Slovenia where the hops plants etc. are sourced in the Lower Savinja valley. The coordinating party is the Slovenian Institute of Hop Research and Brewing (IHPS) supported by Savinja Development Agency. Along with Zelfo Technology, further project partners include Lankhorst Euronete Group – Portugal (PLA suspension twine developers), Tridas Czech Republic (Pulp Moulded Products) Tecnopackaging – Spain (PLA/Agro residual compounders), TECOS – Slovenia (Plastic Product Developers).

First steps for the project included planting of the hops with the newly developed PLA twine at the project start, followed after the harvest by the sorting and delivery of the hops residual plants/ twine to Zelfo Technology in Schwedt/Oder. Processing of the material in Schwedt took place in late autumn early winter 2019 and the materials were conditioned and shipped to the project partners in good time.

Extremely positive early results have been recorded by the IHPS composting analysis team. Various on site non industrial composting combinations of material layering as well as modulation of the conditions has proven that Lankhorst’s PLA suspension fibre can indeed be completely absorbed into the composted ‘biomass’ without remaining plastic micro-particles. Which on a global level is a very positive sign that BioPlastics may not be such a disposal issue as initially thought.

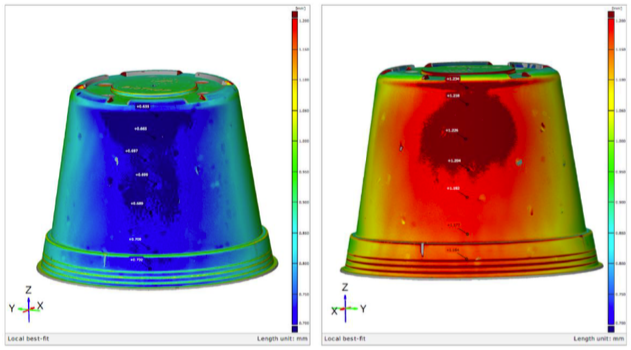

In regard to end products, the first bioplastics test materials using Zelfo Technology fibre together with Tecnopackaging provided PLA were compounded and provided to TECOS for moulding into plant pots. Successful moulding trials followed and the first injection moulded pots have already been assessed by the team. The form of the pot, which was developed at TECOS over several months has met the teams expectations and should meet the design criteria set out by IHPS in regard to ideal nursery conditions for hops plants.

EU development relies on the spread of good practice throughout the continent therefore the group are busy with Europe wide dissemination of the first wave of results, which from an EU LIFE project perspective is fundamental to the program.

This years crop is growing on improved PLA based twines, therefore Lankhorst eagerly await the final assessment of this years material performance.

Since the last harvest, much progress has been made regarding harvesting methods, sorting and storage. Not only will this help with the development of specialist materials, it will also make the analysis of the composting system more precise. This new option will be a key part of the work for the IHPS who have helped drive the pan regional awareness campaign regarding residual materials handling.

Harvest time is rapidly approaching and therefore the next round of activities on the BioTHOP agenda is coming up. These include the further analysis by TECOS of the pot material properties which require performance improvements, they will be supported in this task by Tecnopackaging in regard to material compounding optimisation. Zelfo Technology will also develop closer ties with Tridas in a combined effort to optimise the fibre type and dosing parameters to create market ready bottle dividers for the transportation of bottled beverages.

Tridas will host the next ‘progress update’ meeting at their location in the Czech republic in December 2020. With the project at the halfway mark expectations firm project deliverables will be a main topic on the agenda. Expectations are high and the group look forward to great conclusion to the year.

Contacts

IHPS

Barbara Ceh

email: barbara.ceh@ihps.si or

Lucija Luskar

email: lucija.luskar@ihps.si

Tel: 00386 3 712 1600

Zelfo Technology

Richard Hurding

Tel: 0049 179 924 9534

email: richard.hurding@zelfo-technology.com

Source

BioTHOP, press release, 2020-07-20.

Supplier

Lankhorst Euronete Portugal SA

Slovenian Institute of Hop Research and Brewing (IHPS)

Tecnopackaging

TECOS GmbH

Tridas

Zelfo Technology GmbH

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals