In addition, downstream process models have been developed for the manufacture of diesel, ethanol and methane on the basis of algae. A study conducted using these new models gives an idea of the economic feasibility of algae as a source of energy, and the foremost variables affecting feasibility. The cost of processing the energy products generated from algae appear to be many times higher than the current market sales price.

Microalgal production

Three types of microalgal production systems were studied: open ponds, tubular photobioreactors and flat panel photobioreactors (PBRs). According to the model, the annual algal biomass production in an open pond measuring 1,000 m2 in Lelystad is 1,538 kg of dry mass. This represents 15 tons of dry mass per hectare. The biomass yield per surface area in a tubular PBR is twice as high as in an open pond, and three times as high in a flat panel PBR.

The cost price per 1,000 m2 for producing algal biomass in a PBR is therefore much lower than for algal biomass produced in open ponds. This is largely because of the lower cost of capital items and labour.

The only item that is more expensive for PBRs is the cost of energy. A flat panel PBR shows the lowest algal cost price.

Huge algal production volumes are needed to produce energy carriers from algae. A surface area of 100 ha of open ponds, 50 ha of tubular PBRs or 30 ha of flat panel PBRs is needed to produce around 1,500 tons of dry algal biomass (the minimum volume of algae needed for a digester). The cost per kg of biomass becomes similar for all three systems when the production volumes are this high (approximately €5 per kg of dry mass). Electricity is the highest cost item.

Processing algae into energy carriers

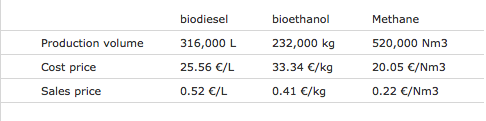

The following table shows the potential production volumes for the energy products from 1.5 million kg of algae. According to the calculation model, the cost prices for processing these energy products are much higher than the current market sales prices.

The cost of the algae is the largest cost item. But even if algae were freely available, the downstream process costs would still be higher than the sales price. So a significant drop in the production and processing costs is needed before algae can be used as a source of energy.

The cost of the algae is the largest cost item. But even if algae were freely available, the downstream process costs would still be higher than the sales price. So a significant drop in the production and processing costs is needed before algae can be used as a source of energy.

EnAlgae

EnAlgae brings together 19 partners and 14 observers across seven EU Member States. It is developing sustainable technologies for algal biomass production, bioenergy and greenhouse gas mitigation, taking them from pilot facilities through to market-place products and services. The project is part of the INTERREG IVB NWE programme, which started in 2011 and will end in 2015.

Source

Wageninen UR, press release, 2015-07-28.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals